Difference between revisions of "Processor - basic design"

(→Step 5. (Add methoxide)) |

(→Step 5. (Add methoxide)) |

||

| Line 203: | Line 203: | ||

===Step 5. (Add methoxide)=== | ===Step 5. (Add methoxide)=== | ||

| − | Replace the processor lid and ensure that it is | + | Replace the processor lid and ensure that it is <big>'''completely sealed before''' </big> proceeding. |

With the heater off, valves V2 and V4 open, the pump running and your methoxide container connected to the suction of the venturi, open valve V5 to introduce the Methoxide. This as quickly as your system will allow, unless you are using the pump suction, in which case please pay careful attention to the comments in the ‘Basic design’ section. Close valve V5 once all the Methoxide has been entrained. | With the heater off, valves V2 and V4 open, the pump running and your methoxide container connected to the suction of the venturi, open valve V5 to introduce the Methoxide. This as quickly as your system will allow, unless you are using the pump suction, in which case please pay careful attention to the comments in the ‘Basic design’ section. Close valve V5 once all the Methoxide has been entrained. | ||

Revision as of 20:13, 28 December 2010

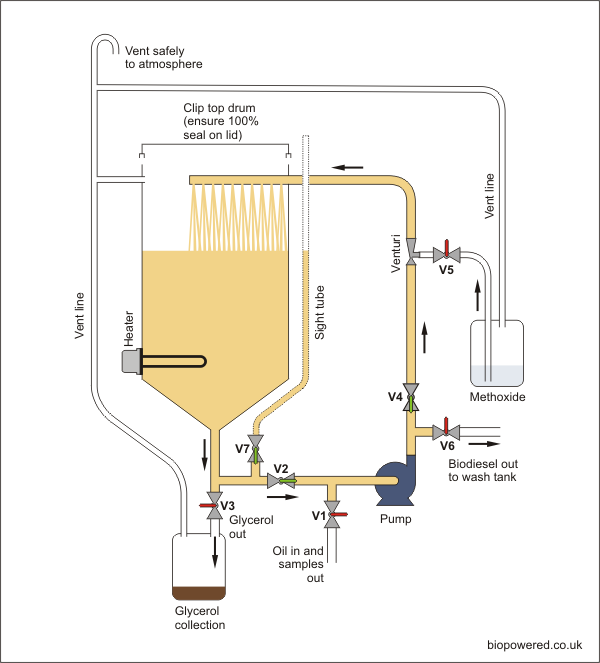

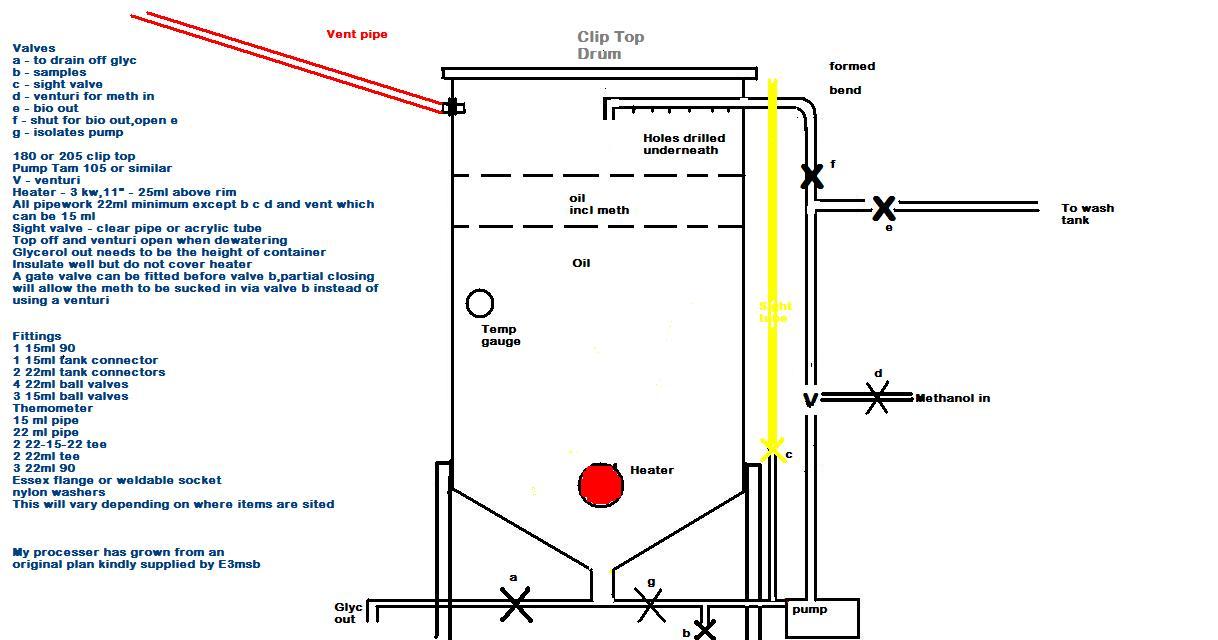

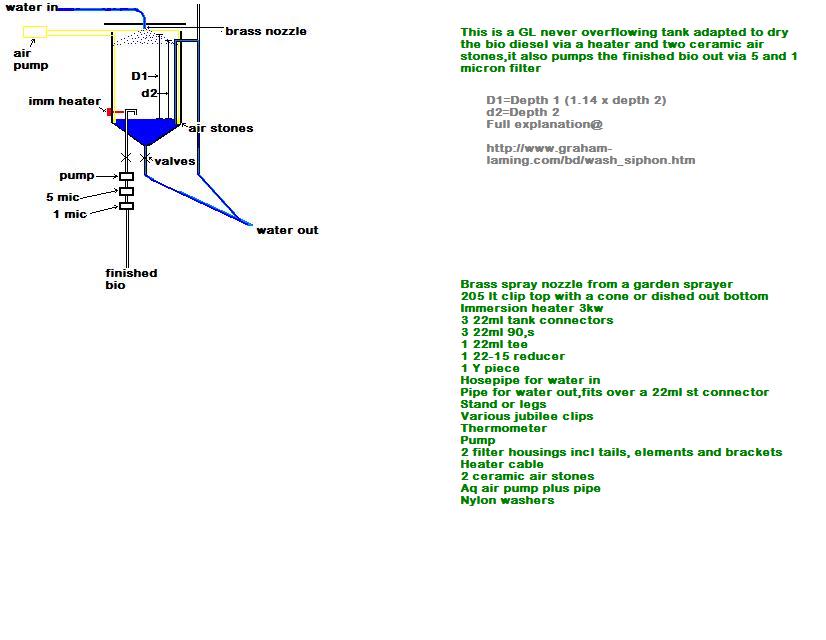

This is probably one of the least complicated processor designs and is suited to those new to Biodiesel production and is similar to the Appleseed processor used extensively in the USA. It can, by quite simple modification, later be upgraded with additional equipment to speed the process and could if required be converted into a GL processor. This design requires a wash tank and a separate Methoxide mixer. The wash tank shown is based on a design by Graham Laming, with some minor additions.

Contents

Basic design

As with all processors employing an electrical heater, it is strongly recommended that the heater is interlocked with a processor level switch or that a non siphoning, in-line heater is used.

A 7% water wash can be used with this processor design, but it probably offers little benefit as the design requires additional water washing. It is preferable to retain the glycerol, uncontaminated by water, and use it to Glycerol wash the subsequent batch.

To further simplify the design, the venturi could be dispensed with and the Methoxide introduced via valve V1, using the suction created by the pump. The pump should be running with valves V2 and V4 fully open. Connect your Methoxide container to the 'Oil in' pipe and crack open vale V1. To reduce the possible risks involved with this method only a small flow of Methoxide should be allowed into the stream of circulating oil. It is important to maintain this ratio of oil to Methoxide to ensure no high concentrations of Methoxide pass through the pump. For the little cost and effort involved, it is far preferable from a safety point of view to fit a venturi.

Operating procedure

State diagram

This table tells you about the status of each valve, the heater and pump at various stages of the process.

State diagram: Green = valve open, pump running or heater on.

| Step | Heater | Pump | V1 | V2 | V3 | V4 | V5 | V6 | Notes |

| Oil in | Pre-filter oil. Ensure pump is primed. | ||||||||

| Heat oil | 70 -90°C | Remove processor lid. Only heat to 60°C if Glycerol washing, see state separate diagram. | |||||||

| Dry oil | 70 -90°C | Drain any settled water via V1 before starting pump. Disconnect V6 from methoxide container so venturi can draw air. | |||||||

| Cool oil | Allow to stand until oil reaches reaction temperature of 64°C. | ||||||||

| Add methoxide | Replace reactor lid and ensure it seals completely. | ||||||||

| Reaction stage | React for about 1½ hrs or until 3/27 pass is achieved. If required 7% water wash can be carried out once the reaction is complete, see additional state diagram below. | ||||||||

| Settle glycerol | Circa 1hr | ||||||||

| Drain glycerol | Crack open valve V3 and slowly drain Glycerol. | ||||||||

| Transfer to wash tank | See separate state diagram for wash procedure |

Step 1. (Oil in)

Your oil storage tank should be connected to the 'Oil In' pipe. The oil in the storage tank should be above the level of the pump if your pump is not self-priming so the suction is flooded.

Open valves V1, V4 and V7, and turn on the pump.

Your oil must be free of large chunks of debris, so your pump doesn't jam. There is no need to filter it (all the fine bits and pieces will end up in your glycerol layer). It must have no visible water in it.

Open valve V1 to load oil into the reactor. Shut valve V1 when the oil level in the reactor reaches approximately 70% of its capacity. This will leave the correct amount of space for the methoxide which you will add later.

Step 2. (Heat Oil)

Remove the processor lid and check that the heating element is completely covered by the oil.

Open valves V2 and V4, and start the pump running to re-circulate oil around the tank.

Switch on the heater if you are CERTAIN that the reactor is filled above the element and that the pump is running. It is dangerous to add heat if the level is too low, because you may expose the heating element, which would then overheat and ignite the oil in the tank. You could have a tank fire.

You must run the pump whenever the heater is on, so that there is a steady flow of oil to cool the element.

Heat to 70-90°C (you generally find what works best for you after a few batches) and leave to settle for a short period unless you intend to Glycerol wash, see below. Once up to temperature you can switch everything off and after a short period, drain any water which has dropped out or carry on with the drying process.

Step 3. (Dry oil)

Remove the processor lid.

With the heater and pump running oil will circulate around the processor via the sparge pipe where oil is sprayed through the air within the tank. This process exposes a large surface area of oil to the atmosphere allowing water to evaporate. See the video clip at the top of the page where you can see steam escaping from the oil. A fan blowing air into the top of the tank will speed the process.

Continue this process until the oil passes a hot pan test.

Step 4. (Cool oil)

Once dry, allow the oil to cool to the reaction temperature of 64°C. Leaving the lid off the processor will speed things up.

Step 5. (Add methoxide)

Replace the processor lid and ensure that it is completely sealed before proceeding.

With the heater off, valves V2 and V4 open, the pump running and your methoxide container connected to the suction of the venturi, open valve V5 to introduce the Methoxide. This as quickly as your system will allow, unless you are using the pump suction, in which case please pay careful attention to the comments in the ‘Basic design’ section. Close valve V5 once all the Methoxide has been entrained.

Step 6. (Reaction stage)

Step 7. (Settle glycerol)

Step 8. (Drain glycerol)

Step 9. (Transfer to wash tank)

Glycerol wash

State diagram

5% water pre-wash

State diagram

Water wash

State diagram

Possible additional modifications

Higher performance pump

The basic design employs typically a TAM 105 or a Leo XKM60 based on an 80 - 100 litre batch size, but a pump with a capacity of around 100 – 150 litres/min. could be used giving a reduction in processing time

Low oil level interlock

The one flaw with this design of processor is the possibility of running the heater, part of which is exposed above a low liquid level. Two methods of preventing this have been introduced, both of which interlock with the heater to prevent it being switched on when the oil in the processor is below a predetermined level.

Non siphoning, in-line heater

Devised by Graham Laming, this unit comprises a small tank fitted with flow and return ports and housing a heating element. It is designed in such a way that liquid is trapped in the tank even when the system is drained. They remove the need for an in-tank heating element but are not in themselves fool proof.

See In-line heater

Mixing eductor

This is a devise mounted inside the processor operating on the venturi principal and driven by the existing pump. It creates a turbulent circulation within the tank and significantly reduces processing times.

See Mixing eductor

PID temperature controller

Instead of using the thermostat built into immersion heaters many users are now employing PID controllers. These units control to a far greater accuracy, without hysteresis, and across a broader temperature range.

See PID controller

Fill processer to required level,turn on pump and heater and circulate with lid off and venturi open (if applicable) until required temperature is reached (70 – 90 C ) Replace lid and settle overnight then drain off any water,perform a hot pan test to verify the oil is dry Titrate and set level,turn on heater and pump until 64C is reached,turn off heater and introduce methoxide via pump or venturi Circulate for x amount of time (x will depend on pump size,typically ½ hour – 1 ½ hours ) Perform 27/3 or 5/45 test at 20C continue circulating until a pass is achieved Prewash – if required Slowly add 7% water and ciculate for 15 minutes Close bottom valve and settle for at least 1 hour then drain glycerol Transfer to wash tank Wash until water is clear,perform 50/50 soap test to confirm Allow to settle for 1 hour then drain water,turn on heater (optional) and airstones and bubble overnight to dry Pump through chosen filters to holding tank Instead of drying the wvo by heat and circulation you can perform a glycerol prewash which will also lower the titration value Fill processer to required level turn on heater and pump then heat to 60C Turn off heater and add 20% glycerol,circulate for ½ hour then settle for 1 hour before draining off glycerol Titrate as normal You can speed up your processing times by adding things like an eductor

From a safety point of view i would recommend fitting a float switch or an inline heater so that the heater cannot be turned on unless it is covered