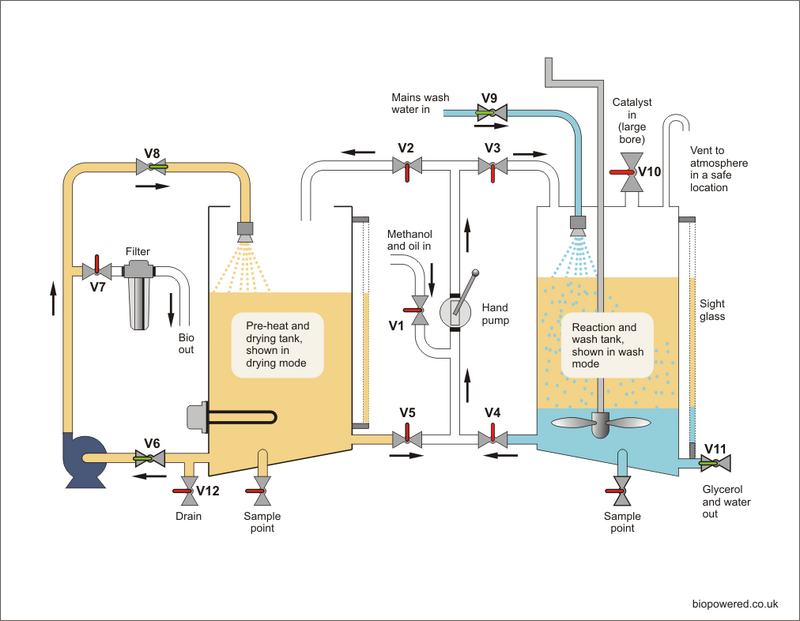

Processor - with pre-heat / drying tank

While processors systems can have several tanks, a system employing just two tanks has been developed by Goat Industries in the UK to try and eliminate as many hazards as possible. As the design concept precludes the use of electrical power after the initial heating of the oil, water washing is used for final Methanol and soap removal after draining the Glycerol. Although not a flexible design in terms of recovering Methanol, it’s probably one of the safest. Once any soap, excess Methanol and catalyst have been removed in the wash water, the Biodiesel is pumped back to the first tank for spray drying.

Contents

- 1 Basic design

- 2 Operating procedure

- 2.1 State diagram for a processor with preheat/drying tank

- 2.2 Step 1. (Oil In)

- 2.3 Step 2. (Heat the Oil)

- 2.4 Step 3. (Dry the oil)

- 2.5 Step 4. (Add Methanol)

- 2.6 Step 5. (Add Catalyst)

- 2.7 Step 6. (Add oil to Methoxide)

- 2.8 Step 7. (Purge pipe work)

- 2.9 Step 8. (Settle the glycerol)

- 2.10 Step 9. (Drain the glycerol)

- 2.11 Step 10. (Water wash)

- 2.12 Step 11. (Drain oil from heating/drying tank)

- 2.13 Step 12. (Transfer Biodiesel)

- 2.14 Step 13. (Heat Biodiesel)

- 2.15 Step 14. (Dry Biodiesel)

- 2.16 Step 15. (Pump out Biodiesel)

Basic design

The design ensures that all the electrics and heaters are located in one tank, while the reaction with Methanol takes place in a second, separate tank. The temperatures required for biodiesel production of around 60°C presents no flammability or toxic risks in respect of vegetable oil or finished Biodiesel, provided the heating element is always submerged in liquid, so the oil is heated using an electrical heating element which is interlocked with a level switch in a dedicated tank.

The Methanol and catalyst is mixed to make Methoxide in the sealed reactor tank by a manually powered paddle arrangement. The preheated oil is then manually pumped into the Methoxide thus making it an AAF reaction.

It is important with this design that the height of the Methanol and oil inlet is above the maximum liquid level in both tanks, preferably above the tank tops, to prevent any back flow of liquids when the valves are operated.

The valve (V11) is used for draining both Glycerol and wash water. You should check with your local Water Authority, but wash water can normally be discharged to the sewer (not a surface water drain). However, Glycerol should be collected in a suitable container and disposed of in an appropriate manner. When draining Glycerol ensure that the work space is well ventilated and avoid breathing any fumes during the process.

Wetted components of the hand pump must be compatible with vegetable oil, Methanol and Biodiesel.

It is imperative that paddle arrangement is securely mounted at the top of the tank with a sealed, well lubricated bearing and that the bottom section is prevented from excess movement which might allow it to come in contact with the sides or bottom of the tank.

Operating procedure

State diagram for a processor with preheat/drying tank

This table tells you about the status of each valve, the heater and pumps at various stages of the process.

State diagram: Green = valve open, pump running or heater on.

| Step | Heater | Hand Pump |

Elect. Pump |

V1 | V2 | V3 | V4 | V5 | V6 | V7 | V8 | V9 | V10 | V11 | V12 | Notes |

| Oil in | Pre-filtered. | |||||||||||||||

| Heat the oil | 80°C | Drain any accumulated water through V12. If the oil requires further drying, step 3 can commence at 40-50°C. | ||||||||||||||

| Dry the oil | 80°C | Dry until hot pan test gives a pass. | ||||||||||||||

| Add Methanol | Disconnect electrics. | |||||||||||||||

| Add Catalyst | Close V10 immediately after introduction of catalyst and thoroughly mix with paddle. | |||||||||||||||

| Add oil to Methoxide | Slowly introduce oil to Methoxide whilst mixing with the paddle. Ensure temperature does not exceed 50°C. | |||||||||||||||

| Purge pipe work | To remove ant traces of Methanol or Methoxide from interconnecting pipe work. | |||||||||||||||

| Settle the glycerol | 90 mins. if an additional settling tank is being used, 3-5 days if transferring direct to the car. | |||||||||||||||

| Drain the glycerol | Crack open valve V11 and slowly drain the glycerol into a suitable container. | |||||||||||||||

| Water wash | Adj. | Adj. | Balance valves V9 and V11 to ensure a constant water level without Biodiesel running out of V11 or the tank overfilling in which case biodiesel will be forced out of the vent. | |||||||||||||

| Drain oil from heating/drying | Drain as well as possible to avoid contaminating the Biodiesel. | |||||||||||||||

| Transfer Biodiesel | ||||||||||||||||

| Heat Biodiesel | 60°C | When up to temperature drain any water which has dropped out of the Biodiesel. | ||||||||||||||

| Dry Biodiesel | Until sample remains clear at room temperature. | |||||||||||||||

| Pump out Biodiesel | Pump into vehicle tank or suitable storage. |

Step 1. (Oil In)

Your oil storage and settling tank should be piped to the 'Methanol and oil in' connection. Your oil must be free of large chunks of debris, so your pumps don't jam, however, it’s preferable to filter or settle out all the fine bits and pieces as these may harbour water. The oil must have no visible water in it. Open valves V1 and V2 and using the hand pump fill the heating/drying tank.

Stop pumping when the oil level in the heating/drying tank reaches 75% of the reactor tank capacity. This will leave the correct amount of space for the methoxide which will be mixed in the reactor tank before the oil is added.

Step 2. (Heat the Oil)

Heat the oil to 80°C and drain any accumulated water through V12.

Step 3. (Dry the oil)

Dry oil is vital. Wet oil can create a soap-gel in your reactor tank, which can easily block pipe work. Most used oil contains a large amount of water, even though it may look clear, so it’s recommended you de-water your oil. With the oil at 80°C, open valves V6 and V8 and run the electric pump. Hot oil is now circulating through the spray nozzle. As it travels through the air and water will evaporate off. To aid removal of the of moist air a fan can be arranged to blow into the drum.

Step 4. (Add Methanol)

Ensure that the work area is well ventilated, open valves V1 and V3 and operate the hand pump to introduce the Methanol to the reactor tank.

Step 5. (Add Catalyst)

Having titrated your oil, weigh out the appropriate quantity of catalyst. Using a funnel in V10, open the valve and introduce the catalyst bit by bit stirring with the paddle as you do so. Close V10 once all the catalyst has been added.

Mix thoroughly using the paddle. The catalyst will have a tendency to clump together and, this being the case, you may hear it swirling in the bottom of the tank. Continue mixing until it can no longer be heard. This is an exothermic reaction and the temperature of the Methoxide will rise during mixing.

Step 6. (Add oil to Methoxide)

Ensure the power supply to the processor is switched off and disconnected.

The oil in the pre-heat/drying tank should be around 70-80°C. The reaction temperature required is between 50°C and 60°C. Open valves V5 and V3 and pump oil into the reactor tank using the hand pump, giving the occasion stir with the paddle. When all the oil has been added to the reactor, the temperature should be in the range indicated above. However, as this is an AAF reaction, the initial introduction of oil to an excess of Methoxide will result in an initial temperature rise.

The mix should not be allowed to rise above 60°C, if it approaches this temperature, stop adding oil and allow cool. Continue adding oil, mixing periodically until all the oil has been introduced and then mix thoroughly for at least 10 minutes.

Step 7. (Purge pipe work)

There will still be a little Methanol left in the pipe work. This can now be purged with the Biodiesel mix by opening vales V3 and V4 and operating the hand pump until the pipe work is flushed out.

Step 8. (Settle the glycerol)

At least 5 days should be allowed for the Glycerol to settle out of the Biodiesel before washing and using it in an engine. If an additional settling tank is used, the majority of the Glycerol will have settled within 90 minutes and can be drained into a suitable container for disposal. The biodiesel can then be washed and further settled.

Step 9. (Drain the glycerol)

Crack open valve V11 and slowly drain the glycerol into a suitable container. Draining slowly will prevent any turbulence and ensure a clean split with the Biodiesel.

Step 10. (Water wash)

Connect a mains water supply and crack open valve V9. Washing needs to be quite gentle at first as vigorous washing can cause an emulsion. Allow the water spray to drop through the Biodiesel and build up at the bottom of the tank. As it dose so, soap, Glycerol and any remaining Methanol will go into solution and get carried to the bottom with the water droplets.

Once the water level is visible in the sight tube, valve V11 can be cracked open and a sample taken. This should be checked for any signs of emulsions. It should appear milky white with no signs of Biodiesel. If the sample is satisfactory, valve V11 can be opened to start draining off the wash water via a suitable hose connection. The aim should be to balance valves V9 and V11 to maintain a stable level in the tank. A careful eye should be kept on the operation as too much flow through V11 will result in loss of Biodiesel to the drain and insufficient flow through V11will result in loss of Biodiesel via the vent.

Washing should continue until the wash water runs clear.

Step 11. (Drain oil from heating/drying tank)

Step 12. (Transfer Biodiesel)

Step 13. (Heat Biodiesel)

Step 14. (Dry Biodiesel)

Step 15. (Pump out Biodiesel)

The Twyn Tub or 'TT' range of processors are an industrial type of design that produces biodiesel to the European standard, EN14214. The process starts off in the left hand tank, that has heating elements inserted and the main reaction takes place in the right hand tank, which is compltely free of any electrical items. The plant was designed to be as safe as reasonly possible without using extortionately expensive components and isolating the reaction stage of the process was found to be the most cost effective way of doing this.

- TT700A

In the photo above, it can be seen that an air operated main pump and mixing ram is used ,whilst smaller models can be hand operated. The left hand heating tank is open at the top and has a high quality level sensor built into it's side to ensure that the heater elements are not turned on accidentally. Most accidents in making biodiesel have been caused this way, especially if the plant design allows methanol vapour to be present at any time in the heating tank during the process. This design does not allow this to happen.

The plant has a large number of valves, inlets and outlets to enable the pumps to work in a large number of different permutations, making the plant as a whole extremely flexible. A separate, electric pump, is used on the left hand side to avoid contamination of the final product with fluids in the main air operated pump. The process uses water to purify the biodiesel, with spray nozzles for washing and drying. No ionic exchange resins are used as these turn the soaps back to acids which are corrosive to vehicle engine parts.