Difference between revisions of "Processor - with methanol condenser (GL design)"

| Line 242: | Line 242: | ||

<td></td> | <td></td> | ||

<td></td> | <td></td> | ||

| − | <td></td> | + | <td>Pre-filtered</td> |

</tr> | </tr> | ||

<tr> | <tr> | ||

| Line 255: | Line 255: | ||

<td></td> | <td></td> | ||

<td></td> | <td></td> | ||

| − | <td></td> | + | <td>Check level before applying heat</td> |

</tr> | </tr> | ||

<tr> | <tr> | ||

| Line 268: | Line 268: | ||

<td></td> | <td></td> | ||

<td></td> | <td></td> | ||

| − | <td></td> | + | <td>Switch to 50°C when O/P slows</td> |

</tr> | </tr> | ||

<tr> | <tr> | ||

<td>Cool oil</td> | <td>Cool oil</td> | ||

| + | <td>50°C</td> | ||

<td></td> | <td></td> | ||

<td></td> | <td></td> | ||

| Line 280: | Line 281: | ||

<td></td> | <td></td> | ||

<td></td> | <td></td> | ||

| − | <td> | + | <td>Titrate oil now. Empty collector.</td> |

| − | |||

</tr> | </tr> | ||

<tr> | <tr> | ||

| Line 294: | Line 294: | ||

<td></td> | <td></td> | ||

<td></td> | <td></td> | ||

| − | <td></td> | + | <td>Allow 20 mins to inject.</td> |

</tr> | </tr> | ||

<tr> | <tr> | ||

| Line 307: | Line 307: | ||

<td></td> | <td></td> | ||

<td></td> | <td></td> | ||

| − | <td></td> | + | <td>Allow 90 mins at 50C</td> |

</tr> | </tr> | ||

<tr> | <tr> | ||

| Line 320: | Line 320: | ||

<td></td> | <td></td> | ||

<td></td> | <td></td> | ||

| − | <td></td> | + | <td>Mix 15 mins</td> |

</tr> | </tr> | ||

<tr> | <tr> | ||

| Line 333: | Line 333: | ||

<td></td> | <td></td> | ||

<td></td> | <td></td> | ||

| − | <td></td> | + | <td>Wait 90 mins</td> |

</tr> | </tr> | ||

<tr> | <tr> | ||

| Line 346: | Line 346: | ||

<td></td> | <td></td> | ||

<td></td> | <td></td> | ||

| − | <td></td> | + | <td>Drain slowly to avoid whirlpool</td> |

</tr> | </tr> | ||

<tr> | <tr> | ||

| Line 373: | Line 373: | ||

<td></td> | <td></td> | ||

<td></td> | <td></td> | ||

| − | <td></td> | + | <td>Ensure heater is OFF first! Caution - Hot! Wear breathing apparatus. |

| + | Take sample and perform 23/7 test before discharging whole batch.</td> | ||

</tr> | </tr> | ||

</table> | </table> | ||

Revision as of 23:30, 12 December 2010

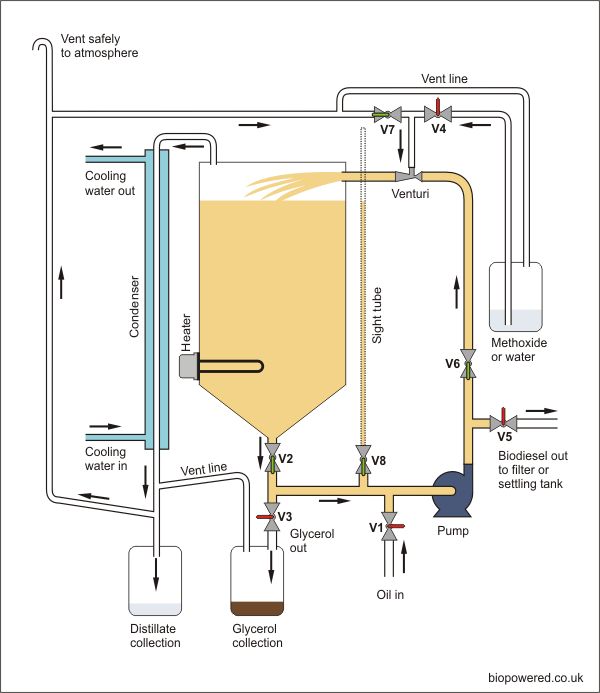

The GL Processor is a design by Graham Laming (hence the GL) and has probably become most popular processor design for homebrew biodiesel production in the UK. The processor features built in dewatering and Methanol recovery capabilities, as well as protection against user exposure to Methanol vapour. The design also lends itself to a variety of production techniques.

Basic design

The design has been in existence for many years. It has been supplemented and improved by various users during this time. Below is a schematic of Graham’s basic design (with sight glass added) along with instructions on its use. Reproduced with kind permission from Graham. Although the design has been modified by others, Graham’s basic design is capable producing high quality Biodiesel and due to its simplicity of design is suitable for those new to home production.

This is a compact home made biodiesel processor which avoids water-washing and limits methanol release to very small amounts. You can also recover surplus Methanol from your biodiesel, which would otherwise be lost in the wash water.

You can de-water your oil in the processor and you can start to recover methanol from as low as 40 degrees C.

Here's a diagram of the system. It includes a simple venturi to recirculate vapour through a condenser. The venturi also sucks methoxide (or water, if you do the 5% prewash) from the methoxide container and mixes it into the oil flow.

Allow a straight horizontal run of around 30cm after the venturi outlet to ensure the venturi will perform properly. This is because the momentum of the out-flowing liquid acts to "pull" on the inlet vapour.

You can mount the Methoxide tank up, nearer the venturi, if your venturi's performance is marginal. Make sure it is not too high - you don't want to drop the container, spill the methoxide, or hurt your back.

State diagram for the Basic GL processor

| State diagram: Green = open valve, or power applied | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Step | Heater | Pump | V11 | V2 | V3 | V4 | V5 | V6 | V7 | Notes | |||

| Oil in | Pre-filtered | ||||||||||||

| Heat Oil | 50C | Check level before applying heat | |||||||||||

| Dewater oil | 90C | Switch to 50C when O/P slows | |||||||||||

| Cool oil | 50C | Titrate oil now. Empty collector. I use NaOH | |||||||||||

| Inject Methoxide | Adj. | Allow 20 mins to inject. | |||||||||||

| Reaction Stage | Allow 90 mins at 50C | ||||||||||||

| 5% Prewash | Mix 15 mins | ||||||||||||

| Settle Glycerol | Wait 90 mins | ||||||||||||

| Drain Glycerol | Drain slowly to avoid whirlpool | ||||||||||||

| Distil methanol | 90C | ||||||||||||

| Drain Biodiesel | off | Adj. | Ensure heater is OFF first! Caution - Hot! Wear breathing apparatus. Take sample and perform 23/7 test before discharging whole batch. |

||||||||||

| Step | Heater | Pump | V1 | V2 | V3 | V4 | V5 | V6 | V7 | Notes |

| Oil in | Pre-filtered | |||||||||

| Heat Oil | 50°C | Check level before applying heat | ||||||||

| Dewater oil | 90°C | Switch to 50°C when O/P slows | ||||||||

| Cool oil | 50°C | Titrate oil now. Empty collector. | ||||||||

| Inject Methoxide | Adj. | Allow 20 mins to inject. | ||||||||

| Reaction Stage | Allow 90 mins at 50C | |||||||||

| 5% Prewash | Mix 15 mins | |||||||||

| Settle Glycerol | Wait 90 mins | |||||||||

| Drain Glycerol | Drain slowly to avoid whirlpool | |||||||||

| Distil methanol | 90°C | |||||||||

| Drain Biodiesel | Off | Adj. | Ensure heater is OFF first! Caution - Hot! Wear breathing apparatus. Take sample and perform 23/7 test before discharging whole batch. |