Water washing

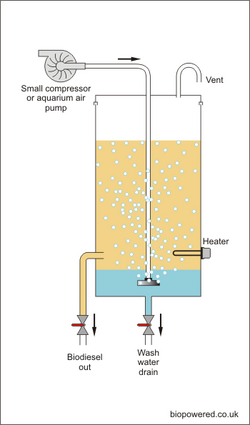

Water washing is a way to remove soap and other contaminants from reacted biodiesel. Typically this involves mist spraying water over the biodiesel, or bubbling air through water with the biodiesel floating on top.

Water washing is a different process to the water prewash process which is a form of water washing carried out in the processor before the glycerol is drained off.

Even the best quality Biodiesel will contain some level of contaminants. Many of these are water soluble such as soaps, Glycerol, Methanol and catalyst. Water washing removes these contaminants quite effectively however it leaves the Biodiesel containing trace amounts of water which need to be removed by an additional drying process. Water washing should ideally be performed 18 hours after the glycerol is drained. This gives the bulk of contaminants time to settle out and makes the job of washing easer and quicker. It is preferable that this settling is carried out in a separate tank and then transferred to a wash tank for the wash process.

Basic wash tank

Water washing is a way to remove soap from reacted biodiesel. Typically this involves mist spraying water over the biodiesel, or bubbling air through water with the biodiesel floating on top.

Water prewash is a form of water washing, although this is done in the processor before the glycerol is drained

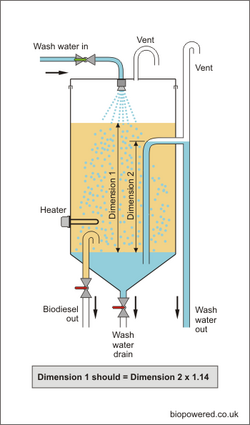

GL wash tank

Originally designed by Graham Laming and dubbed 'The never overflowing wash tank’, this design automatically drains the same volume of water as is being introduced.

This simple layout automatically keeps the level in the tank fixed. As you add water via a spray or mist head, it passes through the biodiesel, taking methanol, soap and glycerol with it, and then collects in the bottom of the tank, where it is forced up, by the weight of biodiesel on top of it, through a drain pipe, to drain off as much water as is added. It is arranged in a way which prevents it from siphoning uncontrollably.

The biodiesel outlet tube on the left is bent over with a U joint, to prevent water from entering the biodiesel drain pipe during washing.

Fill the tank with water first, to about ½ way between the biodiesel drain tube and the bottom of the tank. This should be around 15% of the tank capacity.

Caution: This system will work so long as the wash water can freely pass through the drain tube. Therefore, do not use this system in winter, where freezing of either the biodiesel or the water may occur. Use a large bore drain pipe to minimise the risk of it becoming blocked.