Difference between revisions of "Tips and wrinkles 1"

(→Drip catcher) |

|||

| (57 intermediate revisions by 6 users not shown) | |||

| Line 1: | Line 1: | ||

There must be numerous homebrew biodiesel plants where the owners have added little modifications to improve performance or to make life easer for the operator. This page is intended to detail these wrinkles in the hope that they will be of benefit to others. | There must be numerous homebrew biodiesel plants where the owners have added little modifications to improve performance or to make life easer for the operator. This page is intended to detail these wrinkles in the hope that they will be of benefit to others. | ||

| + | |||

| + | See also [[tips and wrinkles 2]]. | ||

__TOC__ | __TOC__ | ||

| Line 17: | Line 19: | ||

[[User:Bio-rich-time-poor|Bio-rich-time-poor]] 00:26, 8 May 2011 (BST) | [[User:Bio-rich-time-poor|Bio-rich-time-poor]] 00:26, 8 May 2011 (BST) | ||

| + | |||

| + | |||

==Spill gutter== | ==Spill gutter== | ||

| Line 24: | Line 28: | ||

<gallery caption="Spill gutter" widths="400px" heights="350px" perrow="2" align="center"> | <gallery caption="Spill gutter" widths="400px" heights="350px" perrow="2" align="center"> | ||

| − | File:. | + | File:Gutter1.JPG|Guttering catching any spills. |

| − | File:. | + | File:Gutter2.JPG|Which then drains into a bucket. |

</gallery> | </gallery> | ||

[[User:Bio-rich-time-poor|Bio-rich-time-poor]] 00:26, 8 May 2011 (BST) | [[User:Bio-rich-time-poor|Bio-rich-time-poor]] 00:26, 8 May 2011 (BST) | ||

| − | |||

==Condenser tell-tail== | ==Condenser tell-tail== | ||

| − | To get an indication of possible [[plumbers delight|condenser]] performance problems, a tell tail can be installed on the vapour return to the [[venturi]]. Any liquid carryover from the condenser or uncondensed [[ | + | To get an indication of possible [[plumbers delight condenser|condenser]] performance problems, a tell tail can be installed on the vapour return to the [[venturi]]. Any liquid carryover from the condenser or uncondensed [[methanol]] condensing in the vapour return will collect in the pot indicating a problem with the condenser. This will also serve to collect any oil being forced backwards round the vapour circuit, due to valves being opened at the wrong times etc, before it contaminates the condenser. Easily made with a valve, a jam jar and a tank connector. |

| Line 51: | Line 54: | ||

| − | <gallery caption="Foot strainer" widths=" | + | <gallery caption="Foot strainer" widths="250px" heights="250px" perrow="3" align="center"> |

File:Foot strainer 1.JPG|Solder can be seen having run inside the copper band holding the mesh to the body. | File:Foot strainer 1.JPG|Solder can be seen having run inside the copper band holding the mesh to the body. | ||

File:Foot strainer 2.JPG|Top view showing copper band holding mesh and adapter to take 15mm copper pipe. | File:Foot strainer 2.JPG|Top view showing copper band holding mesh and adapter to take 15mm copper pipe. | ||

| Line 80: | Line 83: | ||

| − | <gallery caption="Flying hose holders" widths=" | + | <gallery caption="Flying hose holders" widths="250px" heights="350px" perrow="3" align="center"> |

File:Flying hose holder 1.JPG|Clips used to store hoses upright, preventing drips. | File:Flying hose holder 1.JPG|Clips used to store hoses upright, preventing drips. | ||

File:Flying hose holder 2.JPG|Clip used to hold hose into mouth of sock filter whilst pumping WVO. | File:Flying hose holder 2.JPG|Clip used to hold hose into mouth of sock filter whilst pumping WVO. | ||

| Line 92: | Line 95: | ||

==Winged jubilee clips== | ==Winged jubilee clips== | ||

| − | If you use flying hoses to move oil, glycerol or | + | If you use flying hoses to move oil, glycerol or biodiesel around these make life a whole lot easer. It’s not an original idea, but it’s a cheap and easy way of making quick to use hose clips. |

Simply file the screw driver slot wider to accept a suitably sized piece of scrap steel, use another piece of scrap for the handle and silver solder the whole lot together. Just ensure you don’t solder the screw mechanism. | Simply file the screw driver slot wider to accept a suitably sized piece of scrap steel, use another piece of scrap for the handle and silver solder the whole lot together. Just ensure you don’t solder the screw mechanism. | ||

| Line 99: | Line 102: | ||

| − | <gallery caption="Winged jubilee clips" widths=" | + | <gallery caption="Winged jubilee clips" widths="250px" heights="250px" perrow="3" align="center"> |

File:Winged jubilee clip 1.JPG|Simply made from scrap and silver soldered together. | File:Winged jubilee clip 1.JPG|Simply made from scrap and silver soldered together. | ||

File:Winged jubilee clip 2.JPG|Tightened with one hand, no screwdriver to find or to slip off the screw. | File:Winged jubilee clip 2.JPG|Tightened with one hand, no screwdriver to find or to slip off the screw. | ||

| + | File:Winged jubilee clip kh.jpg|Another version using half a washer. Source K.H | ||

</gallery> | </gallery> | ||

| Line 156: | Line 160: | ||

Course sock filters can be made from surplus, woven, polypropylene landscaping fabric and finer ones from old bed sheets. The suspension collar can be made from an off cut of garden hose and stitching can be done with a simple domestic sewing machine. | Course sock filters can be made from surplus, woven, polypropylene landscaping fabric and finer ones from old bed sheets. The suspension collar can be made from an off cut of garden hose and stitching can be done with a simple domestic sewing machine. | ||

| − | Dimensions will obviously vary according to requirements, but typically start with a rectangle, the length of which equal to the height of the sock required. The width will be dictated by the length of garden hose used to create the collar. Provided the collar is about 25mm than the hole in which the sock is suspended it shouldn’t pull through, even when full of oil. Make the width the length of the hose plus 50mm to allow for two seams. | + | Dimensions will obviously vary according to requirements, but typically start with a rectangle, the length of which equal to the height of the sock required. The width will be dictated by the length of garden hose used to create the collar. Provided the diameter of the collar is about 25mm larger than the hole in which the sock is suspended it shouldn’t pull through, even when full of oil. Make the width the length of the hose plus 50mm to allow for two seams. |

| − | <gallery caption=" Homemade sock filters " widths=" | + | <gallery caption=" Homemade sock filters " widths="250px" heights="300px" perrow="3" align="center"> |

File:Sock filter diagram.png|Suggested method of constructing home made sock filters. | File:Sock filter diagram.png|Suggested method of constructing home made sock filters. | ||

File:Sock filter 1.JPG|Two filters fitted through a plywood barrel top. The hose pipe collar can just be seen sticking out of the hem on right-hand filter. | File:Sock filter 1.JPG|Two filters fitted through a plywood barrel top. The hose pipe collar can just be seen sticking out of the hem on right-hand filter. | ||

| Line 166: | Line 170: | ||

[[User:Bio-rich-time-poor|Bio-rich-time-poor]] 00:26, 8 May 2011 (BST) | [[User:Bio-rich-time-poor|Bio-rich-time-poor]] 00:26, 8 May 2011 (BST) | ||

| − | |||

| − | |||

==Human centrifuge== | ==Human centrifuge== | ||

| − | When performing [[3/27 test|3/27test]], the process can be speeded up by use of a simple piece of cord. Take a sample of | + | When performing a [[3/27 test|3/27test]], the process can be speeded up by use of a simple piece of cord. Take a sample of biodiesel in a capped sample tube, tie a length of stout chord around the top (a clove hitch works well), so that the lip prevents the cord slipping off. Choose a safe place and whirl the tube around on the chord, the separation between biodiesel and glycerol is surprisingly fast and complete. |

Once the 3/27 test is mixed, the same process can be repeated to speed up the fall out process. | Once the 3/27 test is mixed, the same process can be repeated to speed up the fall out process. | ||

| Line 182: | Line 184: | ||

[[User:Bio-rich-time-poor|Bio-rich-time-poor]] 00:26, 8 May 2011 (BST) | [[User:Bio-rich-time-poor|Bio-rich-time-poor]] 00:26, 8 May 2011 (BST) | ||

| + | ==Strong back dome puller== | ||

| + | Not quite suitable for a bottom drainage dome, but excellent for doming the lid of a clip top drum, this simple strong back idea will pull a dome of around 30mm. | ||

| − | |||

| − | |||

| − | |||

<gallery caption="Dome puller" widths="400px" heights="350px" perrow="2" align="center"> | <gallery caption="Dome puller" widths="400px" heights="350px" perrow="2" align="center"> | ||

| − | File:Strong back 2.jpg|Simple construction and quiet in operation compared to the more common"bashing with a fence post" method. | + | File:Strong back 2.jpg|Simple construction and quiet in operation compared to the more common "bashing with a fence post" method. |

File:Strong back 1.jpg|Note the added lock nut on the face of the lid. The studding needs to be clamped to the lid to prevent the assembly from turning. | File:Strong back 1.jpg|Note the added lock nut on the face of the lid. The studding needs to be clamped to the lid to prevent the assembly from turning. | ||

| − | </gallery | + | </gallery> |

| + | |||

| + | [[User:Rotary-Motion|Rotary-Motion]] 08:30, 9 May 2011 (BST) | ||

| + | |||

| + | |||

| + | ==Black bin liner free heating / settling== | ||

| + | |||

| + | Adding a black bin liner over cubie or carbouy containers helps absorb the suns radiated heat to speed up the settling process and drop the suspended water and fats more quickly. | ||

| + | |||

| + | <gallery caption="Free heat from the sun to aid settling" widths="400px" heights="350px" perrow="2" align="center"> | ||

| + | File:Bin-liner.jpg|2 cubies will fit in 1 standard bin bag liner. | ||

| + | </gallery> | ||

| + | |||

| + | [[User:Rotary-Motion|Rotary-Motion]] 12:42, 9 May 2011 (BST) | ||

| + | |||

| + | |||

| + | ==Wiring diagram with safety features for basic GL system== | ||

| + | |||

| + | Schematic with warning lights and safety features | ||

| + | |||

| + | <gallery caption="The diagram" widths="800px" heights="400px" perrow="2" align="center"> | ||

| + | File:Biodiesel reactor circuit diagram.jpg|Lamps are all neons. | ||

| + | </gallery> | ||

| + | |||

| + | [[User:andymac|andymac]] 17:40, 21 May 2011 (BST) | ||

| + | |||

| + | |||

| + | |||

| + | ==J cloth wrapped filter== | ||

| + | |||

| + | An excelent idea from bobblake is to wrap a J cloth or similar around a filter element which will act as a 'pre-filter'. Held in place with twisted wire or another biodiesel/oil proof material, it's cheap, easly changed and will prolong the life of the element. | ||

| + | |||

| + | <gallery caption="Filter saver" widths="350px" heights="400px" perrow="1" align="center"> | ||

| + | File:Wrapped filter.JPG | ||

| + | </gallery> | ||

| + | [[User:Bio-rich-time-poor|Bio-rich-time-poor]] 12:31, 30 May 2011 (BST) | ||

| + | |||

| + | |||

| + | |||

| + | ==WVO core sample tube== | ||

| + | |||

| + | A great idea comes from Kenr34 on the infopop forum in the US. | ||

| + | |||

| + | This lets us take oil core samples from settling drums, totes, and tanks, by showing the depth from the top [good oil] down to crud or water line. Slowly lower the tube into a tank to the bottom, pull the string to seal off the tube, remove and measure down. Thus allowing us to pump off only the dry and cleaner WVO, leaving the water and junk in the tank for later processing. Cost about $10 to construct and saves us time and money every day. | ||

| + | |||

| + | <gallery caption="Core Sample Tube" widths="350px" heights="500px" perrow="2" align="center"> | ||

| + | File:WVO core sample tube Kenr34-infopop.jpg|Source: Kenr34 | ||

| + | File:WVO core sample tube graphic Kenr34-infopop.jpg|Source: Kenr34 | ||

| + | </gallery> | ||

| + | |||

| + | [[User:Bio-rich-time-poor|Bio-rich-time-poor]] 22:49, 13 June 2011 (BST) | ||

| + | ==Biodiesel powered can crusher== | ||

| + | |||

| + | |||

| + | {{#ev:youtube|F1tGMjp24F4|600|center|Can crushing. Make sure you use a strong plank!}} | ||

| + | [[User:Bio-rich-time-poor|Bio-rich-time-poor]] 00:15, 14 June 2011 (BST) | ||

| + | |||

| + | ==Funnel / bucket filter== | ||

| + | |||

| + | Cheap solution for coarse filtering just buy a set of 3 splatter guards from a pound shop,a cheap large funnel and a bucket | ||

| + | Cut the handles off the splatter guards and glue into place with a polyester resin and cut the bottom off the bucket so it fits into an opening on the tank | ||

| + | |||

| + | <gallery caption="click to enlarge" widths="250px" heights="200px" perrow="3" align="center"> | ||

| + | File: Bucket+splatter_guard.jpg|Bucket version. Source: K.H | ||

| + | File: Filter_bits.jpg|Before. Source: K.H | ||

| + | File: Funnel_filter.jpg|Funnel version. Source: K.H | ||

| + | </gallery> | ||

| + | [[User:KH|KH]] 22:40, 25 June 2011 (BST) | ||

| + | |||

| + | ==Non glugging pourer== | ||

| + | |||

| + | This differs from others in that it doesnt require making a hole in the cubie rendering it useless. | ||

| + | |||

| + | Flexable spout for ease of use. | ||

| + | |||

| + | Very simple and cheap and it only uses the lid. | ||

| + | |||

| + | Parts List: | ||

| + | |||

| + | *10"or so of lge pipe ID25mm OD 30mm, | ||

| + | *26" small pipe ID 6mm OD 9mm, | ||

| + | *lid with a hole cut in it, | ||

| + | *Jubilee clip, | ||

| + | *non rigid glue or silicon etc, | ||

| + | *wire eg coat hanger, | ||

| + | *plastic tank connector, | ||

| + | |||

| + | The tank connector goes in the lid and then fix the large pipe to it with a jubilee clip. | ||

| + | |||

| + | Now glue the smaller pipe inside the large pipe with approx 16" extending out(roughly the measurement from the lid to the opposite top corner), put the stiff wire inside the small pipe and fold to keep in place. | ||

| + | |||

| + | Cut the pipes and wire diagonally so the small pipe is at the top and the bend small pipe so that it goes into the top corner of a cubie. If you leave the tank connector with a bit of movement you can alter where it points when it's tightened up. | ||

| + | |||

| + | <gallery caption="click to enlarge" widths="250px" heights="200px" perrow="3" align="center"> | ||

| + | File: Non_glugging_pourer.jpg|Close up. Source: K.H | ||

| + | File: Parts.jpg|Parts used. Source: K.H | ||

| + | File: The_original_non_glugging_pourer.jpg|Pourer. Source: K.H | ||

| + | </gallery> | ||

| + | [[User:KH|KH]] 22:39, 25 June 2011 (BST) | ||

| + | |||

| + | See also [[tips and wrinkles 2]]. | ||

[[Category:Biodiesel]] | [[Category:Biodiesel]] | ||

[[Category:Processors and equipment]] | [[Category:Processors and equipment]] | ||

Latest revision as of 22:57, 3 March 2013

There must be numerous homebrew biodiesel plants where the owners have added little modifications to improve performance or to make life easer for the operator. This page is intended to detail these wrinkles in the hope that they will be of benefit to others.

See also tips and wrinkles 2.

Contents

- 1 Drip catcher

- 2 Spill gutter

- 3 Condenser tell-tail

- 4 Foot strainer

- 5 Barrel pick up pipe

- 6 Flying hose holders

- 7 Winged jubilee clips

- 8 ’O’ rings used on Acrylic sight glass

- 9 Easily made temperature measurement panel

- 10 Thermocouple pocket

- 11 Homemade sock filters

- 12 Human centrifuge

- 13 Strong back dome puller

- 14 Black bin liner free heating / settling

- 15 Wiring diagram with safety features for basic GL system

- 16 J cloth wrapped filter

- 17 WVO core sample tube

- 18 Biodiesel powered can crusher

- 19 Funnel / bucket filter

- 20 Non glugging pourer

Drip catcher

Prevent sample points dripping on the floor. Made from an aerosol lid and a length of electrical cable. Note some lids may have a breather hole. These can be “welded” closed with a heated screwdriver. A length of copper wire is soldered to the pipe, forming a hook on which to hang the pot. When you want to take a sample, swing the pot out of the way, take the sample and then let the pot swing back to catch the drips.

- Drip catcher

Bio-rich-time-poor 00:26, 8 May 2011 (BST)

Spill gutter

Where storage barrels sit on a bench (this facilitates additional room for cubie or drum storage underneath) a good method of catching spills is to cover the bench in plastic sheet or vinyl flooring and fix a length of guttering to the edge of the bench. In the event of a spill, the oil can be scraped into the gutter and collected in a bucket positioned under the outlet.

- Spill gutter

Bio-rich-time-poor 00:26, 8 May 2011 (BST)

Condenser tell-tail

To get an indication of possible condenser performance problems, a tell tail can be installed on the vapour return to the venturi. Any liquid carryover from the condenser or uncondensed methanol condensing in the vapour return will collect in the pot indicating a problem with the condenser. This will also serve to collect any oil being forced backwards round the vapour circuit, due to valves being opened at the wrong times etc, before it contaminates the condenser. Easily made with a valve, a jam jar and a tank connector.

- Condenser tell-tail

Bio-rich-time-poor 00:26, 8 May 2011 (BST)

Foot strainer

Simply made from an old shower head, some wire mesh and scrap. Unfortunately no photos were taken during construction, but manufacture was thus. All internals of shower head were removed. An adapter was made to allow a length of copper tube to be soldered to the inlet.

A circle of mesh was cut to be larger than the head diameter and the edges bent up to grip the shower head all round. The mesh was then trimmed to leave an up-stand about 3mm high. A length of copper pipe was cut lengthwise to generate a thin strip 4mm wide. The chrome was removed from the edge of the shower head, the mesh put into position and the copper strip wrapped around to hold it all in place. The assembly was then simply soldered together. I was lucky enough to locate some copper mesh but the method should work with steel, or stainless steel, provided it’s clean.

- Foot strainer

Bio-rich-time-poor 00:26, 8 May 2011 (BST)

Barrel pick up pipe

Not liking the idea of drilling holes in plastic barrels, this suction pipe is used in conjunction with a self priming pump and flying hoses to transfer liquids. Using a 180° return bend, it simply hooks over the edge of the barrel. The length is such that it will not pick up dregs from the bottom.

- Pick up pipe

Bio-rich-time-poor 00:26, 8 May 2011 (BST)

Flying hose holders

15mm pipe clips can be used to hold hoses whilst being stored or pumping into containers. Two clips bolted together can hold a hose to a pipe.

- Flying hose holders

Bio-rich-time-poor 00:26, 8 May 2011 (BST)

Winged jubilee clips

If you use flying hoses to move oil, glycerol or biodiesel around these make life a whole lot easer. It’s not an original idea, but it’s a cheap and easy way of making quick to use hose clips.

Simply file the screw driver slot wider to accept a suitably sized piece of scrap steel, use another piece of scrap for the handle and silver solder the whole lot together. Just ensure you don’t solder the screw mechanism.

Although not yet tried, a great idea of using a cut down door key in place of the bits of scrap has been suggested by BioWombat.

- Winged jubilee clips

Bio-rich-time-poor 00:26, 8 May 2011 (BST)

’O’ rings used on Acrylic sight glass

Acrylic is not to be recommended as a sight glass as some types tend to haze and crack over time. To prolong the life of the tube use two suitably sized “O” rings in place of an olive in a compression fitting. This will prevent the olive biting into the tube and creating a weak point which will promote breakage.

- ’O’ rings on Acrylic sight glass

Bio-rich-time-poor 00:26, 8 May 2011 (BST)

Easily made temperature measurement panel

Cheap temperature meters can be had on internet auction sites. A quick and easy way of mounting the readouts is to cut a sheet of steel or aluminium to suit and mount to a convenient pipe using plumbing pipe clips.

- Temperature panel

Bio-rich-time-poor 00:26, 8 May 2011 (BST)

Thermocouple pocket

If you use thin or exposed junction thermocouples for temperature measurement, then this design of pocket will give accurate measurement in a small diameter pipe, as it provides a long pocket, from which the heat loss is minimal.

The one pictured is totally fabricated, but fittings could be used to ease manufacture.

- Thermocouple pocket

Bio-rich-time-poor 00:26, 8 May 2011 (BST)

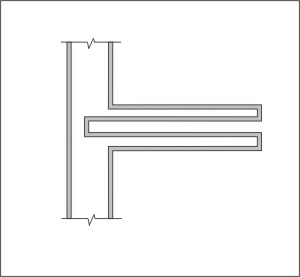

Homemade sock filters

Course sock filters can be made from surplus, woven, polypropylene landscaping fabric and finer ones from old bed sheets. The suspension collar can be made from an off cut of garden hose and stitching can be done with a simple domestic sewing machine.

Dimensions will obviously vary according to requirements, but typically start with a rectangle, the length of which equal to the height of the sock required. The width will be dictated by the length of garden hose used to create the collar. Provided the diameter of the collar is about 25mm larger than the hole in which the sock is suspended it shouldn’t pull through, even when full of oil. Make the width the length of the hose plus 50mm to allow for two seams.

- Homemade sock filters

Bio-rich-time-poor 00:26, 8 May 2011 (BST)

Human centrifuge

When performing a 3/27test, the process can be speeded up by use of a simple piece of cord. Take a sample of biodiesel in a capped sample tube, tie a length of stout chord around the top (a clove hitch works well), so that the lip prevents the cord slipping off. Choose a safe place and whirl the tube around on the chord, the separation between biodiesel and glycerol is surprisingly fast and complete.

Once the 3/27 test is mixed, the same process can be repeated to speed up the fall out process.

- Human centrifuge

Bio-rich-time-poor 00:26, 8 May 2011 (BST)

Strong back dome puller

Not quite suitable for a bottom drainage dome, but excellent for doming the lid of a clip top drum, this simple strong back idea will pull a dome of around 30mm.

- Dome puller

Rotary-Motion 08:30, 9 May 2011 (BST)

Black bin liner free heating / settling

Adding a black bin liner over cubie or carbouy containers helps absorb the suns radiated heat to speed up the settling process and drop the suspended water and fats more quickly.

- Free heat from the sun to aid settling

Rotary-Motion 12:42, 9 May 2011 (BST)

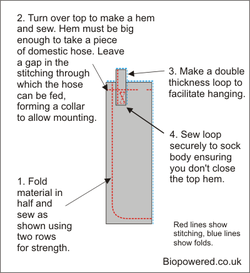

Wiring diagram with safety features for basic GL system

Schematic with warning lights and safety features

- The diagram

andymac 17:40, 21 May 2011 (BST)

J cloth wrapped filter

An excelent idea from bobblake is to wrap a J cloth or similar around a filter element which will act as a 'pre-filter'. Held in place with twisted wire or another biodiesel/oil proof material, it's cheap, easly changed and will prolong the life of the element.

- Filter saver

Bio-rich-time-poor 12:31, 30 May 2011 (BST)

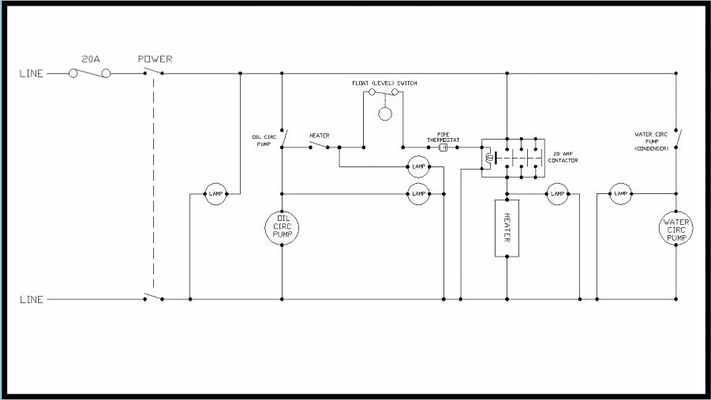

WVO core sample tube

A great idea comes from Kenr34 on the infopop forum in the US.

This lets us take oil core samples from settling drums, totes, and tanks, by showing the depth from the top [good oil] down to crud or water line. Slowly lower the tube into a tank to the bottom, pull the string to seal off the tube, remove and measure down. Thus allowing us to pump off only the dry and cleaner WVO, leaving the water and junk in the tank for later processing. Cost about $10 to construct and saves us time and money every day.

- Core Sample Tube

Bio-rich-time-poor 22:49, 13 June 2011 (BST)

Biodiesel powered can crusher

Bio-rich-time-poor 00:15, 14 June 2011 (BST)

Funnel / bucket filter

Cheap solution for coarse filtering just buy a set of 3 splatter guards from a pound shop,a cheap large funnel and a bucket Cut the handles off the splatter guards and glue into place with a polyester resin and cut the bottom off the bucket so it fits into an opening on the tank

- click to enlarge

KH 22:40, 25 June 2011 (BST)

Non glugging pourer

This differs from others in that it doesnt require making a hole in the cubie rendering it useless.

Flexable spout for ease of use.

Very simple and cheap and it only uses the lid.

Parts List:

- 10"or so of lge pipe ID25mm OD 30mm,

- 26" small pipe ID 6mm OD 9mm,

- lid with a hole cut in it,

- Jubilee clip,

- non rigid glue or silicon etc,

- wire eg coat hanger,

- plastic tank connector,

The tank connector goes in the lid and then fix the large pipe to it with a jubilee clip.

Now glue the smaller pipe inside the large pipe with approx 16" extending out(roughly the measurement from the lid to the opposite top corner), put the stiff wire inside the small pipe and fold to keep in place.

Cut the pipes and wire diagonally so the small pipe is at the top and the bend small pipe so that it goes into the top corner of a cubie. If you leave the tank connector with a bit of movement you can alter where it points when it's tightened up.

- click to enlarge

KH 22:39, 25 June 2011 (BST)

See also tips and wrinkles 2.