Difference between revisions of "Methoxide mixer"

(Added meta description) |

|||

| Line 49: | Line 49: | ||

[[Category:Biodiesel]] | [[Category:Biodiesel]] | ||

| + | [[Category:Biodiesel equipment]] | ||

Revision as of 23:29, 14 January 2011

An important part of any biodiesel processor is the Methoxide mixer. It needs to efficiently and most importantly, safely mix the Methanol and catalyst so the catalyst is completely dissolved in the Methanol.

The two main design criteria are:

- Safety, ensure that the mixer is air tight and vented safely.

- Materials compatibility, ensure all materials used are compatible with Methanol, the catalyst used and the resulting Methoxide mixture.

The following designs are offered as examples; however you should satisfy yourself on the above points before starting construction.

Methoxide mixer design 1

This design is intended for use with a GL type processor which employs a venturi to create a vacuum. I might be possible to connect it via a T piece on a pump suction, but this arrangement has not been tested.

Depending on how extensive your scrap bin or collection of “bits that might come in useful” is, most parts can be made from scrap but it's likely you will need to buy the barrel and the flange bearing. Some items were turned on a lathe but with a bit of ingenuity these could be fabricated. Silver soldering or possibly soldering will be required and welding equipment might be useful.

The barrel is a 25 litre fermenter from an online homebrew beer company. The beauty of this fermenter is that you can buy spare lids separately, with or without holes.

The bearing is readily available from online auction sites or any bearing specialist. Ensure the one you buy has a sealed bearing so there is no leakage of fumes.

This design has two minor draw backs. It won't pick up every last drop of methoxide and due to the size of tubing employed it’s a little slow on delivering Methoxide to the processor, about 1 litre/min with a good vacuum from the venturi. Neither is a major problem and both are far outweighed by its safety and ease of use.

- Methoxide mixer design 1, suitable for a processor with venturi

Bio-rich-time-poor 18:58, 28 November 2010 (UTC)

Methoxide mixer design 2

Contributions needed.

Industrial mixer design 1

This design is suitable for industrial installations where health and safety is a major concern.

Whilst DIY designs are fine for one's own garage or garden shed, where no other person is involved than one's self, an industrial design needs to take more consideration in terms of the risk of accident and needs to be generally more robust and intrinsically safe. Methanol itself is an extremely hazardous chemical and is both highly toxic and inflammable. Methanol fumes are also highly explosive. In an industrial application it is important to minimise the risk to other people and their property in the nearby vacinity.

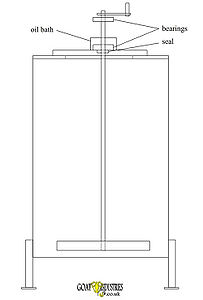

- Goat Industries Methoxide Mixer

This machine features a heavy duty construction that is suitable for industrial use. The main shaft is of such a diameter that it does not vibrate or wobble during operation and the bearings are mounted on heavy steel plate and supported by a hefty gusset (not shown). When in use, the blades, being well supported, will not run the risk of scraping against the side of the container and producing sparks. Also, there is an oil bath to prevent sparks from a semi-siezed up bearing from entering the internals of the vessel.

The photograph shows the valves and tappings needed for efficient use of the machine. The top right valve is positioned to allow a large funnel to be attached, into which the caustic granules are poured. At the very bottom is the main outlet and above that is a sample point for testing the strength of the mix. The main tank is fabricated out of mild steel as this is not 'attacked' by the caustic mix. The mix will attack most plastics and plastic tanks will become hard and brittle and will, in time, fail.