Waste oil filtering system

Waste Vegetable Oil can be collected from numerous outlets, for example; cafes, public houses, restaurants, fish and chips shops - anywhere that uses vegetable oils for cooking. The waste produced can be used as a road fuel, but needs to be cleaned before use in a road vehicle. Waste oil contains impurities from food that have been cooked into it, water, meat, fats, etc. These need to be separated from the oil to make it ready for use. There are alot of different ways to clean oil, all variations on a theme; below is a widely used separation system which a lot of domestic users find best, speeding up the natural process of separation.

See also - Filtering waste vegetable oil

Contents

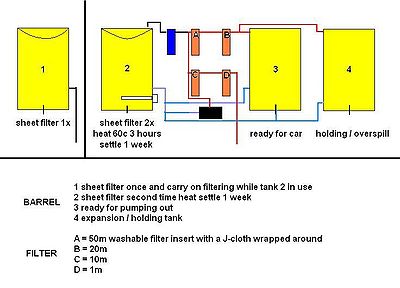

Homemade Filtration System

Parts List

- 22mm copper pipe

- 15mm copper pipe

- 22mm lever valves

- 15mm inline valves

- Copper joints various

- TAM105 electric pump

- Acrylic site tubes

- Filter housings + brackets

- 200 LTR steel barrels + Clamps

- Electrical cable + 3 pin plugs

- Immersion heater element + back nut flange

- Wooden frame base for housing rig

Processing

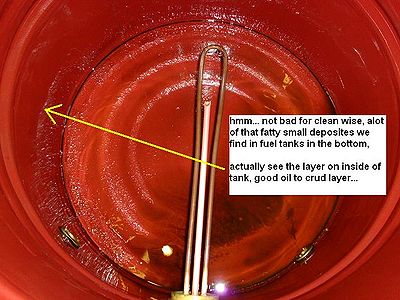

Clamp a cotton sheet over drum for first stage filtering in drum 1 (larger particles) this collects part fats and chips etc, when settled the part filtered oil can be drawn off from a pipe/valve slightly higher than the base (200mm), away from the water and fats settling area (Safe zone/Crud layer). This is now placed in drum 2 for heating upto 60°C (Drying), roughly takes about 3 hours to reach dependant on ambient room temperature. Once heated settle for at least 1 week, water and fats drop faster when heated and cooled/settled. After settling period pump oil through first set of filters into holding drum 3 or 4, oil is pumped through 50 and 20 micron stage filters, gradually reducing the micron at each stage, last set of filtering takes oil through 10 and 1 micron filters when pumped into your desired container for pouring into your vehicle.

- Click pictures to enlarge

Rotary-Motion 17:47, 4 December 2010 (UTC)