Importance of venting a processor

This page will soon be completed by Mark following an intensive and extensive wiki lesson.

Only if he was paying attention.

introduction

All GL reactors need to be vented to alow air to be displaced/replaced when oil/bio is added to or removed from the vessel.

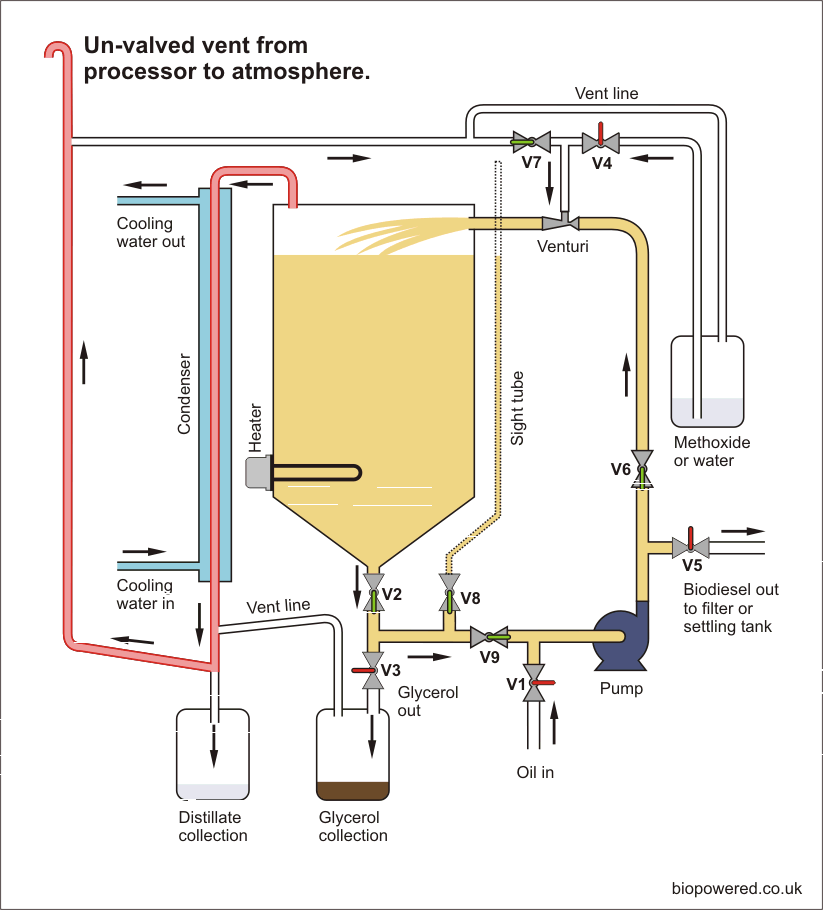

It is important that the vent does not have a valve on it as it must stay open at all times.

Vent layout

The vent on a GL is normally on the vapor line (highlighted in red) after the condenser, this way any methanol fumes that are released during the reaction,

or in the de-meth stage, will get condenced off and collected in the methanol collection vessel.

Concequences

Negative pressure

If the vent becomes blocked it can produce a build up of possative or negative pressure.

This can have sevear effects on the reactor it's self.

Negative pressure can and will cause the reactor to implode as seen in these pictures.

- This is a steel cone bottomed drum

Posative pressure

The most likely way we could produce possative pressure in a GL is by pumping oil into it with a closed vent, allthough in most cases it is unlikely the pump will produce enough presure to cause a problem.

However if a reactor full of cold oil was heated with a closed vent this could build a suprising amount of pressure.

It is possable the the reactor or pipework could rupture, but an exsplotion is highly unlikely in this sinario.