This page is a stub and needs expansion. Your knowledge is valuable to us - please consider sharing it by contributing to this wiki. This page is a stub and needs expansion. Your knowledge is valuable to us - please consider sharing it by contributing to this wiki.

|

These are the essential parts required when building a twin-tank system.

The vehicle is started on mineral Diesel, and then the valves switch over to an auxiliary veg tank when the engine reaches full temperature - the heat exchanger is used to raise the temperature of vegetable oil before it reaches the injection pump, using engine coolant to transfer heat across the plates of the heat exchanger.

Before stopping the engine at the end of a journey, the system must be "Flushed or Purged" with mineral Diesel, making it safe to re-start ie: in the morning from a cold start few hours later. Short stops eg: 30 mins etc 99% of the time shouldnt need to purge/flush down, as the engine will still be upto optimum temperature.

- Click pictures to enlarge

This is a classic flat plate heat exchanger usually salvaged from an old combi boiler.

They come in various sizes determined by the amount of plates (the more the better)

Easily plumbed into your car heater system using existing tails or by fitting 1/2 inch or 3/4 inch hosebarbs respectivly.These are readily available from oilbits in sizes to match your heater hoses ID.

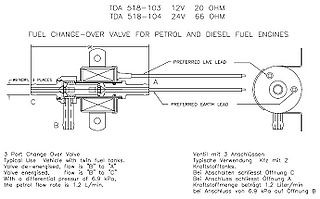

Tecelamit 12 volt valves.

Tecelamit 12 volt valves.

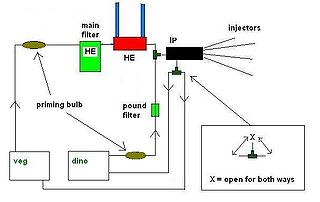

Wiring and plumbing diagram.

One of a number of ways for plumbing in a twin tank system.

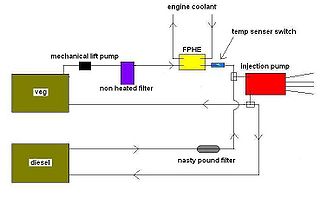

Twin tank system with heated filter and exchanger, switched with inline temperature sensor plus a looped return on vegetable oil fuel tank.

Twin tank system returning both fuels to there individual fuel tanks.

Bottom heated filter, and like the peugeot filter can be modded by removal of the thermostat.

Heater ring that fits standard spin on cartridge type filters.

Temperature sensor electrically switches to live at 60c

Basic in-car switch for changeover from diesel to vegetable oil when optimum engine coolant temperature is reached avg: 80c.

Rotary-Motion 21:50, 5 December 2010 (UTC)