Effect of biodiesel on fuel injection systems

Introduction

This page reproduces information found in the Joint Fuel Injection Equipment Manufacturers Statement, a study by the following manufacturers into the effect of biodiesel (aka FAME) and associated impurities on diesel fuel injection systems.

- Delphi Diesel Systems

- Stanadyne Automotive Corporation

- Denso Corporation

- Robert Bosch GmbH

Contents

Biodiesel and impurities

| Fuel Characteristic | Effect | Failure Mode |

|---|---|---|

| Fatty Acid Methyl Esters (general) | Causes some elastomers including Nitrile rubbers to soften, swell, or harden and crack | Fuel leakage |

| Free Methanol in FAME | Corrodes aluminium & zinc Low flash point |

Corrosion of fuel injection equipment |

| FAME process chemicals | Potassium and sodium compounds Solid particles |

Blocked Nozzles |

| Dissolved water in FAME | Reversion of FAME to fatty acid | Filter Plugging |

| Free water in mixtures | Corrosion Sustains bacteria Increases the electrical conductivity of fuel |

Corrosion of fuel injection equipment Sludging |

| Free glycerine | Corrodes non ferrous metals Soaks cellulose filters Sediments on moving parts Lacquering |

Filter clogging Injector Coking |

| Mono- & di-glyceride | Similar to glycerine | |

| Free Fatty Acid | Provides an electrolyte and hastens the corrosion of zinc Salts of organic acids Organic compounds formed |

Corrosion of fuel injection equipment Filter plugging Sediments on parts |

| Higher modulus of elasticity | Increases injection pressure | Potential of reduced service life |

| High viscosity at low temperature | Generates excessive heat locally in rotary distributor pumps Higher stressed components |

Pump seizures Early life failures Poor nozzle spray atomisation |

| Solid impurities | Potential lubricity problems | Reduced service life |

Ageing products

| Fuel Characteristic | Effect | Failure Mode |

|---|---|---|

| Corrosive acids (formic & acetic) | Corrodes all metallic parts may form simple cell |

Corrosion of fuel injection equipment |

| Higher molecular organic acids | Similar to fatty acid | |

| Polymerisation products | Deposits especially from fuel mixes | Filter plugging Lacquering formation in hot areas |

Considerations for homebrew biodiesel

Note that this section is not part of the document above, but our take as biodiesel homebrewers.

Minimising Free Fatty Acid and mono/diglyceride content

Free Fatty Acids should be removed by the biodiesel process, if the source oil is titrated correctly.

Mono and diglyceride molecules are partly converted vegetable oil (triglyceride) molecules. They are excellent emulsifiers with water, and are often responsible for a white layer in 50/50 soap tests). Complete conversion of vegetable oil into biodiesel will ensure minimum mono and diglyceride content. This can be verified by 27/3 testing the produced fuel.

Removing Methanol and Glycerol

Water washing will remove Methanol and Glycerol, as will Methanol recovery, settling and Dry Washing.

Avoiding polymerisation products

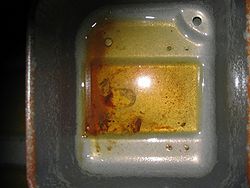

Many biodiesel homebrewers will have seen reddish drop-out in their fuel when mixed with mineral fuels, as highlighted in the Polymerisation products row above. If mixing is required, it is advisable to do this outside of the vehicles tank, and settle for at least 24 hours prior to fuelling.

Fuel storage and oxidisation

As most homebrewers use their fuel within a short period of time after production, most of the negative effects of aging are never seen. That said, be aware that contact with copper (processor pipework or cylinders) reduces the shelf life of biodiesel - even small PPM copper content will act as an oxidisation catalyst for the fuel.

Fuel intended for storage should be kept in a airtight container, that is as full as possible to minimise the quantity of air at the top.

Fuel system and engine care

Biodiesel can have a detrimental effect on fuel system components such as fuel line and pump seals.

The most common problems are with systems employing mechanical injection pumps.

- Injector leak-off return pipes rotting - these are relatively easy to replace on most vehicles - nylon air line makes a good biodiesel-proof replacement

- Injection pump shaft seals leaking

- for gear driven pumps this can mean leaking of fuel into the crankcase oil (look for increasing engine oil level) and contamination of the fuel with engine oil (look for black deposits when the fuel filter is changed).

- for belt driven pumps, failure of this seal usually results in fuel leaking out onto the road, but also possible contact with belts - particularly serious if a cam belt is affected, as biodiesel will rapidly weaken it.

Engine rattling due to air ingress is also a sure sign of seal failure somewhere, though if you're lucky the leak won't be at pump but further back in the fuel system, such as the fuel filter or at tank fittings. A section of clear braided hose (commonly 8mm ID) greatly helps with locating the source of air ingress - put between the fuel filter and the pump and backlit with a torch, any air bubbles will be clearly visible.

Other potential issues include a blocked in-tank coarse filter with soaps or polymerisation products. Some biodiesellers like to remove the in-tank filter and fit a coarse filter before the main filter in the engine bay, where it is more easily accessible for cleaning or replacement.

In all case, it is recommended to change the engine oil twice as frequently as the normal service interval. When diesel contaminates engine oil, over time it can "boil off" with engine heat - however, Biodiesel will remain in the oil and potentially polymerise into a gel over time, blocking oilways or the oil filter.