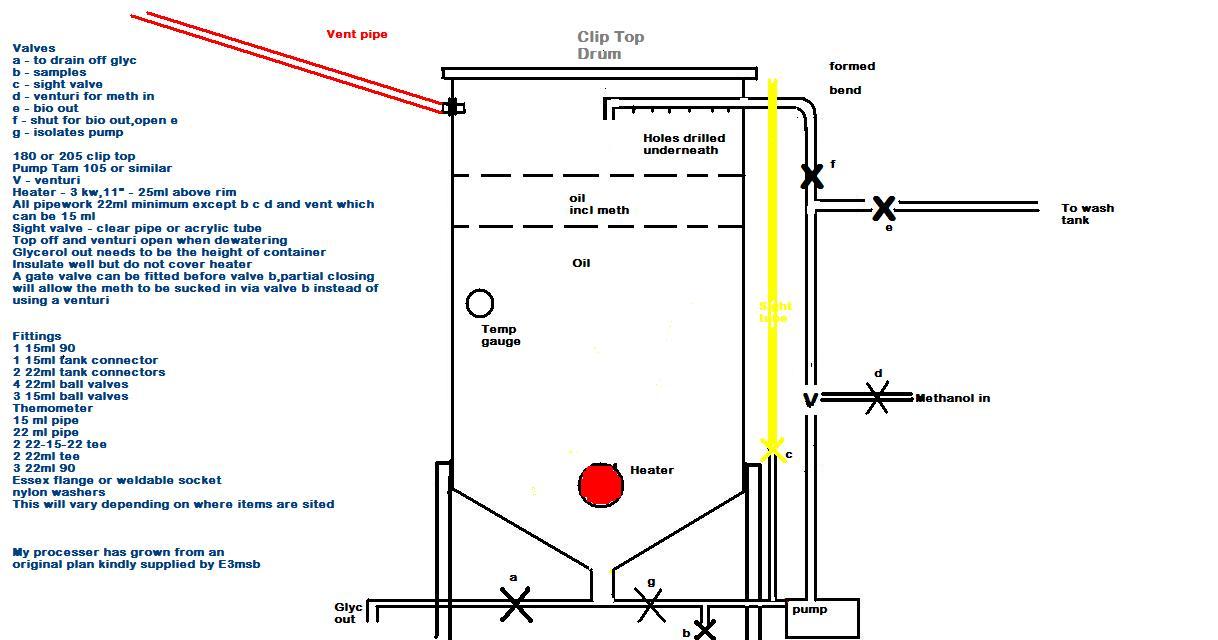

Processor - basic design

A typical two drum processer and method

Fill processer to required level,turn on pump and heater and circulate with lid off and venturi open (if applicable) until required temperature is reached (70 – 90 C )

Replace lid and settle overnight then drain off any water,perform a hot pan test to verify the oil is dry

Titrate and set level,turn on heater and pump until 64C is reached,turn off heater and introduce methoxide via pump or venturi

Circulate for x amount of time (x will depend on pump size,typically ½ hour – 1 ½ hours )

Perform 27/3 or 5/45 test at 20C continue circulating until a pass is achieved

Prewash – if required Slowly add 7% water and ciculate for 15 minutes

Close bottom valve and settle for at least 1 hour then drain glycerol

Transfer to wash tank

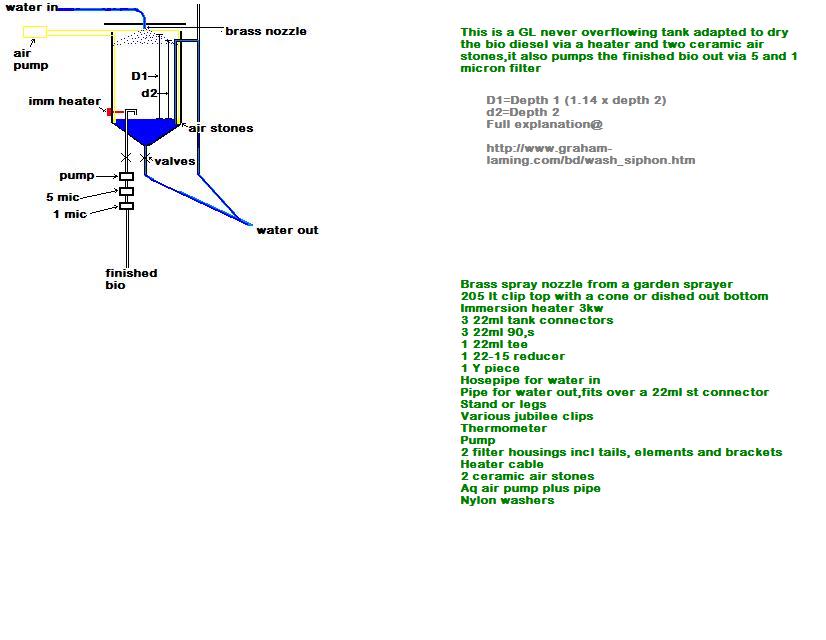

Wash until water is clear,perform 50/50 soap test to confirm

Allow to settle for 1 hour then drain water,turn on heater (optional) and airstones and bubble overnight to dry

Pump through chosen filters to holding tank

Instead of drying the wvo by heat and circulation you can perform a glycerol prewash which will also lower the titration value

Fill processer to required level turn on heater and pump then heat to 60C Turn off heater and add 20% glycerol,circulate for ½ hour then settle for 1 hour before draining off glycerol

Titrate as normal

You can speed up your processing times by add things like an eductor

See clip for an eductor in use