Difference between revisions of "Hot water cylinders"

(More work on cylinders page) |

m (→Types of cylinder) |

||

| Line 12: | Line 12: | ||

Direct cylinders are the obvious choice, followed by indirect - the only disadvantage of indirect is that the coil occupies some of the cylinder's volume. | Direct cylinders are the obvious choice, followed by indirect - the only disadvantage of indirect is that the coil occupies some of the cylinder's volume. | ||

| − | The comparatively rare "primatic" cylinder is unsuitable for use as a biodiesel processor, both because a much larger volume of the cylinder is wasted by the primatic apperatus, and also that not all of the liquid can be drained. If you are unsure if a cylinder is primatic, look into the side ports - if you can see a wall of copper just inside the port, then the cylinder is primatic. If the port forms a tube that bends away to one side, then the cylinder is indirect and you're looking into the end of the coil. | + | The comparatively rare "primatic" cylinder is unsuitable for use as a biodiesel processor, both because a much larger volume of the cylinder is wasted by the primatic apperatus, and also that not all of the liquid can be drained. If you are unsure if a cylinder is primatic, look into the side ports - if you can see a wall of copper just inside the port, then the cylinder is primatic. If the port forms a tube that bends away to one side, then the cylinder is indirect and you're looking into the end of the coil. Another quick check is to jiggle the cylinder - if there is a coil this can be felt wobbling around inside. |

==Hot water cylinder standard sizes== | ==Hot water cylinder standard sizes== | ||

Revision as of 00:33, 28 November 2011

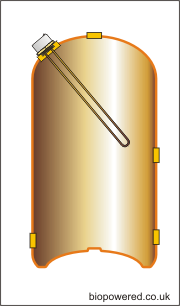

Hot water cylinders are often used to make biodiesel processors. They come with several threaded ports and usually an immersion element. These cylinders are inverted, providing a dome for draining at the bottom, as well as correct placement of the immersion element in relation to the liquid.

Types of cylinder

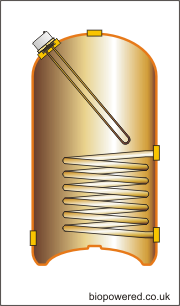

Direct cylinders are the obvious choice, followed by indirect - the only disadvantage of indirect is that the coil occupies some of the cylinder's volume.

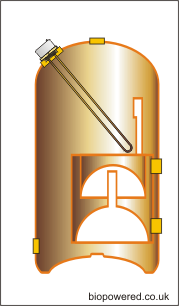

The comparatively rare "primatic" cylinder is unsuitable for use as a biodiesel processor, both because a much larger volume of the cylinder is wasted by the primatic apperatus, and also that not all of the liquid can be drained. If you are unsure if a cylinder is primatic, look into the side ports - if you can see a wall of copper just inside the port, then the cylinder is primatic. If the port forms a tube that bends away to one side, then the cylinder is indirect and you're looking into the end of the coil. Another quick check is to jiggle the cylinder - if there is a coil this can be felt wobbling around inside.

Hot water cylinder standard sizes

| Standard Cylinders | |||||

|---|---|---|---|---|---|

| British standard |

External diameter of cylinder (excluding insulation) |

External height over dome |

Min storage capacity | Expected port fittings | |

| Direct | Indirect | ||||

| mm | mm | Litres | Litres | female, BSP | |

| 0 | 300 | 1600 | 98 | 96 | 1" |

| 1 | 350 | 900 | 74 | 72 | 1" |

| 2 | 400 | 900 | 98 | 96 | 1" |

| 3 | 400 | 1050 | 116 | 114 | 1" |

| 4 | 450 | 675 | 86 | 84 | 1" |

| 5 | 450 | 750 | 98 | 95 | 1" |

| 6 | 450 | 825 | 109 | 106 | 1" |

| 7 | 450 | 900 | 120 | 117 | 1" |

| 8 | 450 | 1050 | 144 | 140 | 1 1/4" |

| 9 | 450 | 1200 | 166 | 162 | 1 1/4" |

| 9e | 450 | 1500 | 210 | 206 | 1 1/4" |

| 10 | 500 | 1200 | 200 | 190 | 1 1/2" |

| 11 | 500 | 1500 | 255 | 245 | 1 1/2" |

| 12 | 600 | 1200 | 290 | 280 | 2" |

| 13 | 600 | 1500 | 370 | 360 | 2" |

| 14 | 600 | 1800 | 450 | 440 | 2" |

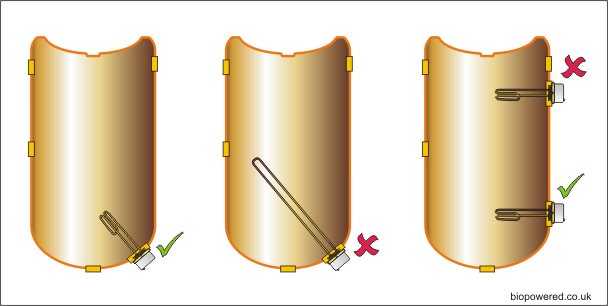

Immersion elements

Before being used as a processor, the heating element should be removed to determine its length. Unless the cylinder is particularly tall, long elements are not suitable, as the tip of the element may protrude above the surface of the oil and Methanol mix, igniting any Methanol vapour present. For this reason, long elements should be replaced with the folded 11" type.