Difference between revisions of "3D Printed parts and spares"

(→Lowara CEAM 70/5-V terminal box) |

|||

| (25 intermediate revisions by the same user not shown) | |||

| Line 5: | Line 5: | ||

At the time of creating this page 3D printing is still in its infancy, but in the belief this technology will become more wide spread, on this page we include some spare parts and small items useful in the home production of biodiesel and WVO preparation. | At the time of creating this page 3D printing is still in its infancy, but in the belief this technology will become more wide spread, on this page we include some spare parts and small items useful in the home production of biodiesel and WVO preparation. | ||

| − | There are currently two types of plastic commonly used for 3D printing, PLA and ABS. Of these two PLA is the easiest to use and appears, from tests so far to be reasonably resistant to biodiesel, methanol and WVO. It has a low melting point and hence can't be used for any high temperature applications and it is '''not''' compatible with any of the catalysts used in biodiesel production. Additionally, due to the way 3D prints are laid down, it is strongly recommended that printed parts are not | + | There are currently two types of plastic commonly used for 3D printing, PLA and ABS. Of these two PLA is the easiest to use and appears, from tests so far to be reasonably resistant to biodiesel, methanol and WVO. It has a low melting point and hence can't be used for any high temperature applications and it is '''not''' compatible with any of the catalysts used in biodiesel production. Additionally, due to the way 3D prints are laid down, it is strongly recommended that printed parts are not used for any pressure applications without rigorous tests being carried out by the person manufacturing the parts. |

It would appear that some of the more commonly used pumps in the UK have terminal boxes manufactured from a plastic that's not compatible with biodiesel. It's hoped that the items below printed in PLA should out last the original parts. | It would appear that some of the more commonly used pumps in the UK have terminal boxes manufactured from a plastic that's not compatible with biodiesel. It's hoped that the items below printed in PLA should out last the original parts. | ||

| + | |||

| + | These designs are offered for personal use only and are used entirely at the printers risk. No liability will be accepted by Biopowered or the creators of these designs as to their suitability for purpose. | ||

<br> | <br> | ||

<br> | <br> | ||

| Line 66: | Line 68: | ||

<br> | <br> | ||

<br> | <br> | ||

| − | |||

| + | ==Land Rover 300 tdi injection pump and flywheel locking tools== | ||

| + | |||

| + | <br> | ||

| + | |||

| + | The flywheel tool requires a 3/16 or 4.7mm diameter drill or pin to engage with the hole in the flywheel (note this is only strong enough to locate TDC, not to undo any bolts etc). As with most prints, the hole may need to be cleared with the drill. The tool has a taper which is intended to bind on the ¼" threads and hold it in place. | ||

| + | |||

| + | The IP locking tool will require two M8 bolts circa. 30mm long to engage with the IP pulley, and a 9.5mm diameter bar to lock the pump flange to the IP body. | ||

| + | |||

| + | Print both with a good wall thickness and fill density. | ||

| + | |||

| + | <br> | ||

| + | |||

| + | <gallery heights="200px" widths="400px" perrow="2" caption="Land Rover 300 tdi IP removal tools" align="center"> | ||

| + | File:Land Rover 300tdi IP locking tool photo.JPG|IP locking tool | ||

| + | File:Land Rover 300tdi flywheel locking tool photo.jpg|Flywheel locking tool | ||

| + | |||

| + | File:Land Rover 300tdi IP locking tool.png|[http://www.biopowered.co.uk/w/images/c/c4/300tdi_IP_locking_tool.stl<font size="3.5" font color = #FF6600>'''Download .stl file'''</font>] | ||

| + | |||

| + | File:Land Rover 300tdi flywheel locking tool.png |[http://www.biopowered.co.uk/w/images/b/ba/300tdi_flywheel_locking_tool.stl<font size="3.5" font color = #FF6600>'''Download .stl file'''</font>] | ||

| + | </gallery> | ||

| + | |||

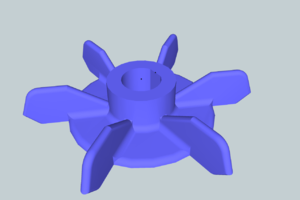

| + | ==TAM 120 replacement cooling fan== | ||

| + | |||

| + | <br> | ||

| + | |||

| + | This broke up possibly due to the plastic splitting following being forced onto the motor shaft. | ||

| + | |||

| + | The replacement was designed to be stronger given the limitations of 3D printing. The shaft boss was increased in diameter and the blade thickness was increased by 1mm. Additionally the boss and all the blades were given a large root radius. | ||

| + | <br> | ||

| + | |||

| + | <gallery heights="200px" widths="400px" perrow="2" caption="TAM 120 replacement cooling fan" align="center"> | ||

| + | File:TAM 120 broken cooling fan.jpg|Broken fan. | ||

| + | File:TAM 120 cooling fan i2.jpg|Printed replacement fitted to motor. | ||

| + | File:Tam 120 cooling fan i2 shaft fit.jpg|As can be seen from the light coloured swarf, the fan's a slight interference fit on the shaft. | ||

| + | |||

| + | |||

| + | |||

| + | File:TAM 120 cooling fan i2.png |[http://www.biopowered.co.uk/w/images/b/bd/TAM_120_cooling_fan_i2.stl<font size="3.5" font color = #FF6600>'''Download .stl file'''</font>] | ||

| + | </gallery> | ||

| + | |||

| + | |||

| + | |||

| + | |||

| + | |||

| + | |||

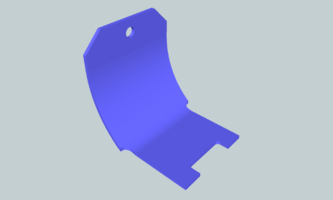

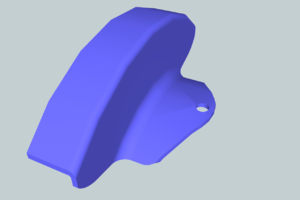

| + | ==Mono ML and MM coupling covers == | ||

| + | |||

| + | <br> | ||

| + | |||

| + | Often missing from second-hand pumps, this version is 2mm thick compared to the originals which are 1.5mm. | ||

| + | |||

| + | Printing on edge with support and no fill should produce good results. Two are required per pump. | ||

| + | <br> | ||

| + | |||

| + | <gallery heights="200px" widths="400px" perrow="2" caption="Mono ML and MM coupling covers" align="center"> | ||

| + | File:Old and new Mono ML covers.jpg|Comparison of original and printed covers. | ||

| + | File:New cover on Mono ML.jpg|Printed cover fitted to pump. | ||

| + | |||

| + | File:Mono ML coupling gaurd.png |[http://www.biopowered.co.uk/w/images/d/d4/Mono_ML_coupling_gaurd.stl<font size="3.5" font color = #FF6600>'''Download .stl file'''</font>] | ||

| + | </gallery> | ||

| + | |||

| + | |||

| + | |||

| + | |||

| + | ==Mono MS coupling covers == | ||

| + | |||

| + | <br> | ||

| + | |||

| + | Often missing from second-hand pumps, this version is 2mm thick compared to the originals which are 1.5mm. | ||

| + | Due to its shape quite a lot of plastic is used for support. Two are required per pump. Unfortunately this cover won't fit the MS predecessor, the M25, which looks similar and was never designed to have a cover. | ||

| + | <br> | ||

| + | |||

| + | <gallery heights="200px" widths="400px" perrow="2" caption="Mono ML and MM coupling covers" align="center"> | ||

| + | File:Mono MS cover printed VS original.JPG|Comparison of original and printed covers. | ||

| + | File:Mono MS cover plastic wasted in support.JPG|Plastic wasted in support. | ||

| + | File:Mono MS cover in fitted.jpg|Printed cover fitted to a rather well used pump. | ||

| + | File:Mono MS gaurd.png|[http://www.biopowered.co.uk/w/images/8/8d/Mono_MS_gaurd.stl<font size="3.5" font color = #FF6600>'''Download .stl file'''</font>] | ||

| + | </gallery> | ||

| + | |||

| + | |||

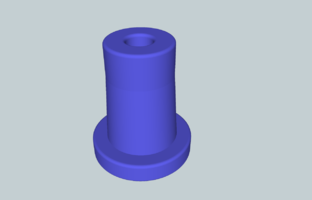

| + | ==20 ltr plastic can adapter == | ||

| + | |||

| + | <br> | ||

| + | |||

| + | A threaded adapter which should fit most 20 ltr plastic cans and allows a 25mm ID PVC pipe to be fixed as a spout. This arrangement is useful for filling vehicle tanks without the aid of a funnel. A vent hole needs to be drilled in the top of the can to admit air. 25mm PVC pipe is available from most aquatic suppliers | ||

| + | |||

| + | A file is included to print the sealing ring using a flexible filament such as Ninja-flex. Alternatively a seal can be cut from a suitable material circa 3-4mm thick with the dimensions ... OD 62mm ID 50mm. | ||

| + | |||

| + | Due to the profile of the threads, the item is best printed at 100% fill, hose tail up and with support. Careful cleaning of the support remnants will be required. | ||

| + | |||

| + | <br> | ||

| + | |||

| + | <gallery heights="200px" widths="400px" perrow="2" caption="20 ltr plastic can adapter" align="center"> | ||

| + | File:Cap2.jpg|Cap and hose fitted to a can ... note the vent hole in the top of the can plugged by a tapered piece of plastic. | ||

| + | File:Cap1.JPG|The 25mm ID tube is quite a tight fit, but a hose clip can be used for additional security. | ||

| + | File:Plastic can cap i1-1.jpg|[http://www.biopowered.co.uk/w/images/a/a6/Plastic_can_cap_1.03.stl<font size="3.5" font color = #FF6600>'''Download .stl file'''</font>] | ||

| + | File:Can cap washer.JPG|[http://www.biopowered.co.uk/w/images/4/49/Can_cap_washer.stl<font size="3.5" font color = #FF6600>'''Download .stl file'''</font>] | ||

| + | |||

| + | </gallery> | ||

| + | |||

| + | |||

| + | |||

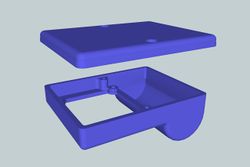

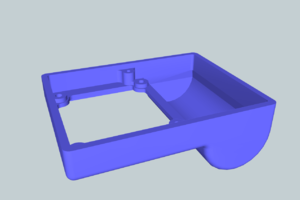

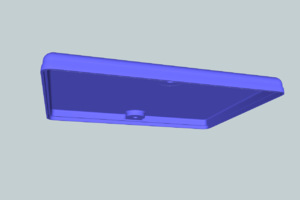

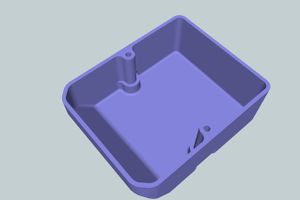

| + | ==Lowara CEAM 70/5-V terminal box== | ||

| + | |||

| + | <br> | ||

| + | |||

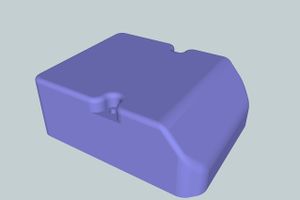

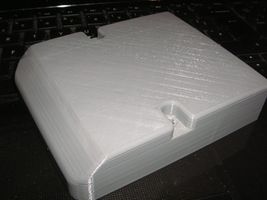

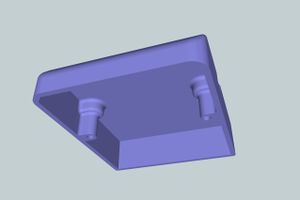

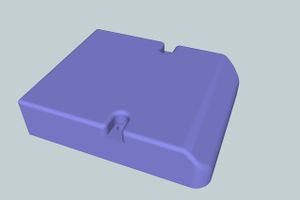

| + | As with many other pumps the terminal box on this Lowara pump doesn't seem to be made to last. The replacement was designed with considerably thicker walls and sturdy reinforcement. Additionally, the capacitor housing was enlarged to make fitting after market capacitors easier. | ||

| + | |||

| + | <br> | ||

| + | |||

| + | <gallery heights="200px" widths="400px" perrow="2" caption="Lowara CEAM 70/5-V terminal box" align="center"> | ||

| + | File:Nige pump term box broke.jpg|The somewhat fragile original terminal box. | ||

| + | File:Lowara terminal box 1.jpg|Thicker walls, enlarged pillars and more room in the capacitor housing. | ||

| + | File:Nige pump term box open.jpg|Assembled on the pump. | ||

| + | File:Nige pump term box closed.jpg|Closed up and sealed for use. | ||

| + | File:Lowara terminal box - bottom.jpg|[http://www.biopowered.co.uk/w/images/d/d7/Lowara_terminal_box_lower.stl<font size="3.5" font color = #FF6600>'''Download .stl file'''</font>] | ||

| + | File:Lowara terminal box cover.jpg|[http://www.biopowered.co.uk/w/images/1/11/Lowara_terminal_box_upper.stl<font size="3.5" font color = #FF6600>'''Download .stl file'''</font>] | ||

| + | |||

| + | </gallery> | ||

| + | |||

| + | |||

| + | <br> | ||

| + | <br> | ||

<br> | <br> | ||

<br> | <br> | ||

Latest revision as of 00:14, 26 April 2016

At the time of creating this page 3D printing is still in its infancy, but in the belief this technology will become more wide spread, on this page we include some spare parts and small items useful in the home production of biodiesel and WVO preparation.

There are currently two types of plastic commonly used for 3D printing, PLA and ABS. Of these two PLA is the easiest to use and appears, from tests so far to be reasonably resistant to biodiesel, methanol and WVO. It has a low melting point and hence can't be used for any high temperature applications and it is not compatible with any of the catalysts used in biodiesel production. Additionally, due to the way 3D prints are laid down, it is strongly recommended that printed parts are not used for any pressure applications without rigorous tests being carried out by the person manufacturing the parts.

It would appear that some of the more commonly used pumps in the UK have terminal boxes manufactured from a plastic that's not compatible with biodiesel. It's hoped that the items below printed in PLA should out last the original parts.

These designs are offered for personal use only and are used entirely at the printers risk. No liability will be accepted by Biopowered or the creators of these designs as to their suitability for purpose.

Contents

TAM 105 terminal box

This box also fits a a GRC Aquatec 82lpm pump. Longer screws may be required as the wall thickness has been increased from the original design.

- TAM 105 replacement terminal box

Bottom section

Download .stl file

TAM 120 terminal box

Fixing pillars within the box have been made considerably stronger by blending them into the box walls.

Longer screws may be required as the wall thickness has been increased from the original design.

- TAM 120 replacement terminal box

Leo XKM60 terminal box

- Leo XKM60 replacement terminal box

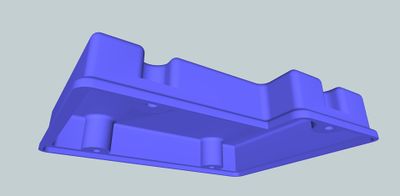

Land Rover 300 tdi injection pump and flywheel locking tools

The flywheel tool requires a 3/16 or 4.7mm diameter drill or pin to engage with the hole in the flywheel (note this is only strong enough to locate TDC, not to undo any bolts etc). As with most prints, the hole may need to be cleared with the drill. The tool has a taper which is intended to bind on the ¼" threads and hold it in place.

The IP locking tool will require two M8 bolts circa. 30mm long to engage with the IP pulley, and a 9.5mm diameter bar to lock the pump flange to the IP body.

Print both with a good wall thickness and fill density.

- Land Rover 300 tdi IP removal tools

TAM 120 replacement cooling fan

This broke up possibly due to the plastic splitting following being forced onto the motor shaft.

The replacement was designed to be stronger given the limitations of 3D printing. The shaft boss was increased in diameter and the blade thickness was increased by 1mm. Additionally the boss and all the blades were given a large root radius.

- TAM 120 replacement cooling fan

Mono ML and MM coupling covers

Often missing from second-hand pumps, this version is 2mm thick compared to the originals which are 1.5mm.

Printing on edge with support and no fill should produce good results. Two are required per pump.

- Mono ML and MM coupling covers

Mono MS coupling covers

Often missing from second-hand pumps, this version is 2mm thick compared to the originals which are 1.5mm.

Due to its shape quite a lot of plastic is used for support. Two are required per pump. Unfortunately this cover won't fit the MS predecessor, the M25, which looks similar and was never designed to have a cover.

- Mono ML and MM coupling covers

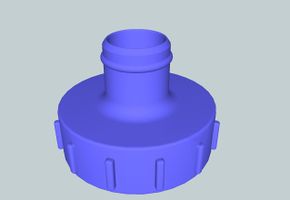

20 ltr plastic can adapter

A threaded adapter which should fit most 20 ltr plastic cans and allows a 25mm ID PVC pipe to be fixed as a spout. This arrangement is useful for filling vehicle tanks without the aid of a funnel. A vent hole needs to be drilled in the top of the can to admit air. 25mm PVC pipe is available from most aquatic suppliers

A file is included to print the sealing ring using a flexible filament such as Ninja-flex. Alternatively a seal can be cut from a suitable material circa 3-4mm thick with the dimensions ... OD 62mm ID 50mm.

Due to the profile of the threads, the item is best printed at 100% fill, hose tail up and with support. Careful cleaning of the support remnants will be required.

- 20 ltr plastic can adapter

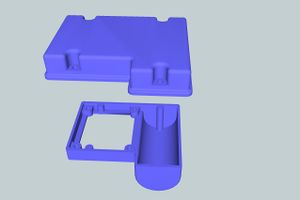

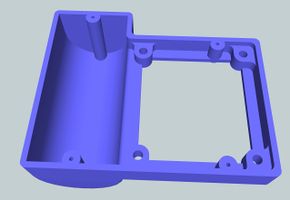

Lowara CEAM 70/5-V terminal box

As with many other pumps the terminal box on this Lowara pump doesn't seem to be made to last. The replacement was designed with considerably thicker walls and sturdy reinforcement. Additionally, the capacitor housing was enlarged to make fitting after market capacitors easier.

- Lowara CEAM 70/5-V terminal box