Difference between revisions of "3D Printed parts and spares"

| Line 5: | Line 5: | ||

At the time of creating this page 3D printing is still in its infancy, but in the belief this technology will become more wide spread, on this page we include some spare parts and small items useful in the home production of biodiesel and WVO preparation. | At the time of creating this page 3D printing is still in its infancy, but in the belief this technology will become more wide spread, on this page we include some spare parts and small items useful in the home production of biodiesel and WVO preparation. | ||

| − | There are currently two types of plastic commonly used for 3D printing, PLA and ABS. Of these two PLA is the easiest to use and appears, from tests so far to be reasonably resistant to biodiesel, methanol and WVO. It has a low melting point and hence can't be used for any high temperature applications and it is '''not''' compatible with any of the catalysts used in biodiesel production. Additionally, due to the way 3D prints are laid down, it is strongly recommended that printed parts are not | + | There are currently two types of plastic commonly used for 3D printing, PLA and ABS. Of these two PLA is the easiest to use and appears, from tests so far to be reasonably resistant to biodiesel, methanol and WVO. It has a low melting point and hence can't be used for any high temperature applications and it is '''not''' compatible with any of the catalysts used in biodiesel production. Additionally, due to the way 3D prints are laid down, it is strongly recommended that printed parts are not used for any pressure applications without rigorous tests being carried out by the person manufacturing the parts. |

It would appear that some of the more commonly used pumps in the UK have terminal boxes manufactured from a plastic that's not compatible with biodiesel. It's hoped that the items below printed in PLA should out last the original parts. | It would appear that some of the more commonly used pumps in the UK have terminal boxes manufactured from a plastic that's not compatible with biodiesel. It's hoped that the items below printed in PLA should out last the original parts. | ||

Revision as of 14:36, 25 February 2015

At the time of creating this page 3D printing is still in its infancy, but in the belief this technology will become more wide spread, on this page we include some spare parts and small items useful in the home production of biodiesel and WVO preparation.

There are currently two types of plastic commonly used for 3D printing, PLA and ABS. Of these two PLA is the easiest to use and appears, from tests so far to be reasonably resistant to biodiesel, methanol and WVO. It has a low melting point and hence can't be used for any high temperature applications and it is not compatible with any of the catalysts used in biodiesel production. Additionally, due to the way 3D prints are laid down, it is strongly recommended that printed parts are not used for any pressure applications without rigorous tests being carried out by the person manufacturing the parts.

It would appear that some of the more commonly used pumps in the UK have terminal boxes manufactured from a plastic that's not compatible with biodiesel. It's hoped that the items below printed in PLA should out last the original parts.

Contents

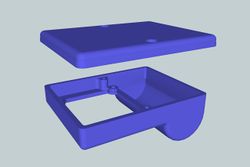

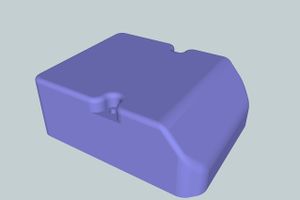

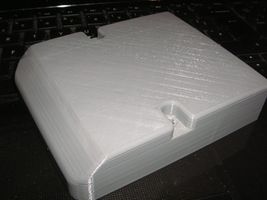

TAM 105 terminal box

This box also fits a a GRC Aquatec 82lpm pump. Longer screws may be required as the wall thickness has been increased from the original design.

- TAM 105 replacement terminal box

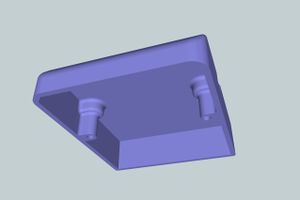

Bottom section

Download .stl file

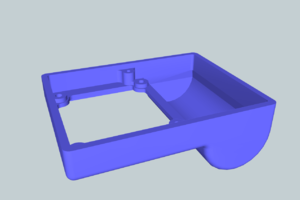

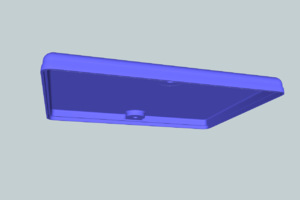

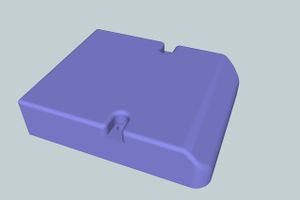

TAM 120 terminal box

Fixing pillars within the box have been made considerably stronger by blending them into the box walls.

Longer screws may be required as the wall thickness has been increased from the original design.

- TAM 120 replacement terminal box

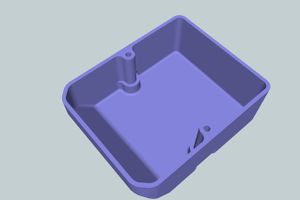

Leo XKM60 terminal box

- Leo XKM60 replacement terminal box

Small foot for 6mm tubing