Difference between revisions of "Still head heat exchanger"

| Line 1: | Line 1: | ||

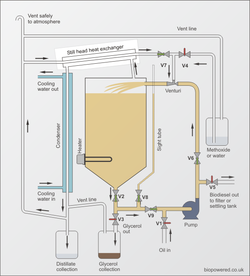

[[File:GL processor with valve to allow use of sight tube and SHHE.png|250px|thumb|right|Schematic showing location of SHHE]] | [[File:GL processor with valve to allow use of sight tube and SHHE.png|250px|thumb|right|Schematic showing location of SHHE]] | ||

| − | Still head heat exchanger (SHHE) is often used on biodiesel reactors to improve the efficiency of the condenser. | + | Still head heat exchanger (SHHE) is often used on biodiesel reactors to improve the efficiency of the [[Plumbers delight condenser|condenser]]. |

SHHE are used with reactor designs that employ methanol recovery. | SHHE are used with reactor designs that employ methanol recovery. | ||

| Line 15: | Line 15: | ||

==Benefits== | ==Benefits== | ||

| − | *Reduces De-meth | + | *Reduces De-meth times |

*Reduces Power consumption of the immersion heater | *Reduces Power consumption of the immersion heater | ||

*Reduces the heat transferred to the cooling water | *Reduces the heat transferred to the cooling water | ||

==Description== | ==Description== | ||

| − | The still head heat exchanger is a vapour to air heat exchanger, transferring heat from water or methanol vapour exiting the reactor to air returning from the condenser to the reactor. | + | The still head heat exchanger is a vapour to air heat exchanger, transferring heat from water or [[methanol]] vapour exiting the reactor to air returning from the condenser to the reactor. |

==Placement== | ==Placement== | ||

Placement of the heat exchanger needs to be done so that any condensed vapour can drain into the collection vessel. | Placement of the heat exchanger needs to be done so that any condensed vapour can drain into the collection vessel. | ||

| − | Often on the GL Eco reactor design SHHE are placed above the condenser to aid draining also being close to the return path of vapour from the condenser to the venturi | + | Often on the [[Processor - with methanol condenser (GL design)|GL Eco]] reactor design SHHE are placed above the condenser to aid draining also being close to the return path of vapour from the condenser to the [[venturi]]. |

==Examples== | ==Examples== | ||

| Line 44: | Line 44: | ||

| − | <gallery caption="SHHE using a flat plate heat exchanger." widths="500px" heights="300px" perrow=" | + | <gallery caption="SHHE using a flat plate heat exchanger." widths="500px" heights="300px" perrow="1" align="center"> |

File:FPHH as SHHE source Ian.jpg|FPHE as a SHHE. source: IanFiTheDwarf1 | File:FPHH as SHHE source Ian.jpg|FPHE as a SHHE. source: IanFiTheDwarf1 | ||

</gallery> | </gallery> | ||

Latest revision as of 21:25, 3 March 2013

Still head heat exchanger (SHHE) is often used on biodiesel reactors to improve the efficiency of the condenser. SHHE are used with reactor designs that employ methanol recovery.

Contents

Benefits

- Reduces De-meth times

- Reduces Power consumption of the immersion heater

- Reduces the heat transferred to the cooling water

Description

The still head heat exchanger is a vapour to air heat exchanger, transferring heat from water or methanol vapour exiting the reactor to air returning from the condenser to the reactor.

Placement

Placement of the heat exchanger needs to be done so that any condensed vapour can drain into the collection vessel. Often on the GL Eco reactor design SHHE are placed above the condenser to aid draining also being close to the return path of vapour from the condenser to the venturi.

Examples

Often heat exchangers from domestic boilers are used, these have a large surface area which improves heat transfer.

- Multi core SHHE by mark

Finished assembly. SHHE and Plumbers delight condenser (both multi core) Source: mark

- SHHE using a commercially made heat exchanger.

- SHHE using a flat plate heat exchanger.