This might shed some light on pipework sizing:

In biodiesel manufacture, not only are we using a pump for moving fluid around, we're also using it for mixing. This is a bit of an odd requirement for a pump - they're normally designed to achieve a required pressure for pushing fluid down a pipe. In our application, pressure needs to be around ~0.2 bar to push it back to the reaction vessel - but we need a massive flow rate to get the mixing we want. This is well outside the bounds of the optimum operating point of most pumps (one of the reasons why eductors work so well in our application), but there are a few things we can do to help matters.

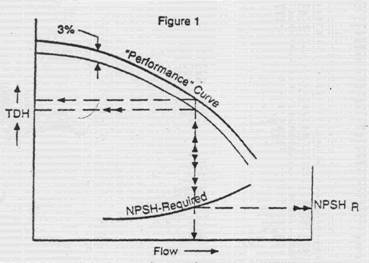

In the graph above, you can see how suction pressure varies with pump flow rate. To get the maximum flow, we need to minimise the pressure drop down the suction pipe. Generally speaking, this is more critical than the pressure drop in the discharge pipe because the pumps we're using have a design point with more pressure than we're putting on them.

You can also spin the pump faster than the design speed. Great if you've got a VFD driving your pump, more difficult if not. You really do need to ensure that you've got a good pressure on the inlet though - too fast and you run the risk of cavitating. I found my pump starts to cavitate at about 85Hz - it also pulls far too much current at this speed, but 60 works very well. It's hard to do a like for like comparison of flow rates without flow meters, but the pressure gauge on the discharge sits about 0.05 bar higher than at 50 Hz.