Difference between revisions of "Processor - with methanol condenser (GL design)"

| Line 1: | Line 1: | ||

{{WIP}} | {{WIP}} | ||

| + | [[File:Graham laming.gif|250px|thumb|Graham Laming with GL processor. Source GL]] | ||

| + | |||

| + | |||

| + | |||

| + | |||

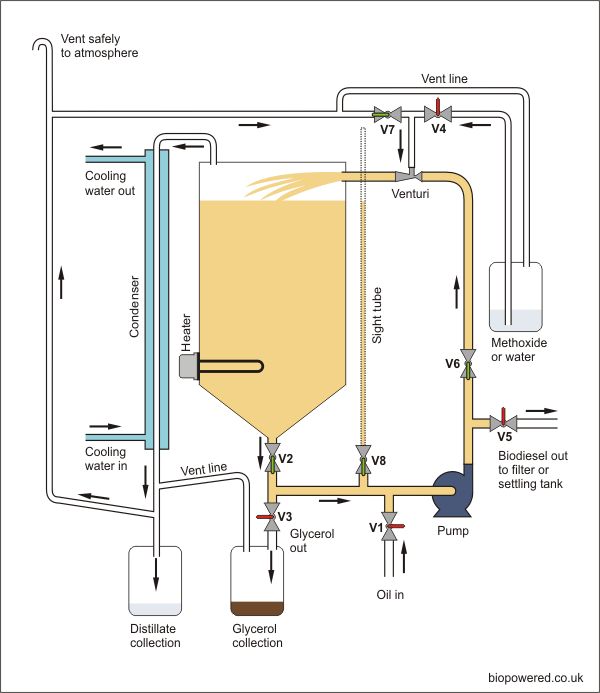

| + | The GL Processor is a design by [http://www.graham-laming.com/bd/ecosystem/state_diagram_new.htm GL Processor](thus the GL) and has probably become most popular processor design for homebrew biodiesel production in the UK. The processor features built in dewatering and Methanol recovery capabilities, as well as protection against user exposure to Methanol vapour. The design also lends itself to a variety of production techniques. | ||

| − | |||

Modern adaptions use a more powerful pump to drive the venturi (typically Clarke's [[Tam 105|TAM105]]) and employ inline heaters or a liquid level deadlock to reduce the risk of accidental explosive ignition of the Methanol vapour, caused by the element becoming exposed above the liquid level. | Modern adaptions use a more powerful pump to drive the venturi (typically Clarke's [[Tam 105|TAM105]]) and employ inline heaters or a liquid level deadlock to reduce the risk of accidental explosive ignition of the Methanol vapour, caused by the element becoming exposed above the liquid level. | ||

| Line 8: | Line 13: | ||

| − | |||

Revision as of 21:24, 12 December 2010

The GL Processor is a design by GL Processor(thus the GL) and has probably become most popular processor design for homebrew biodiesel production in the UK. The processor features built in dewatering and Methanol recovery capabilities, as well as protection against user exposure to Methanol vapour. The design also lends itself to a variety of production techniques.

Modern adaptions use a more powerful pump to drive the venturi (typically Clarke's TAM105) and employ inline heaters or a liquid level deadlock to reduce the risk of accidental explosive ignition of the Methanol vapour, caused by the element becoming exposed above the liquid level.