Multi-tasking processor

Waste Vegetable Oil can be collected from numerous outlets, for example; cafes, public houses, restaurants, fish and chips shops - anywhere that uses vegetable oils for cooking. The waste produced can be used as a road fuel, but needs to be cleaned before use in a road vehicle. Waste oil contains impurities from food that have been cooked into it, water, meat, fats, etc. These need to be separated from the oil to make it ready for use. There are alot of different ways to clean oil, all variations on a theme; below is a widely used separation system which a lot of domestic users find best, speeding up the natural process of separation.

See also - Filtering waste vegetable oil

3 in 1 Processing System.

A filter system which includes a bypass to keep the filters within there pressure rating, basic biodiesel processor and dispensing unit.

Build and design by K.H

Parts List

- 4mts 22mm pipe

- 2x 3/4 hosetails

- 5mt clear 1" pipe

- 8x tees 22mm

- 7x 90s 22mm

- 2x 45 22mm

- 2x bypass valve 22mm

- 5x tank connectors 22mm

- 5x nylon washers

- 5x joiners 22mm

- 4x 3/4"-22mm

- 9x full bore valves 22mm

- 2x pressure gauges

- 18" immersion heater

- 3x 10" filters plus brackets/elements

- mechanical flange 2 1/4"

- 400mic drum filter

- 205lt clip top drum

- 120lt HDPE clip top drum

- tam 105 pump

- 2x 1"-22mm

- 4 mt flex

- 2 plugs

- 22-15-22 tee

- 1x 15mm ball valve

- 1x 15mm tank connector

- 1x 15mm comp 90

- 1x 15 comp tee

- 1x 15mm speedfit stopend

- 4x nylon washers

- 1x float switch

- 1x Connection box

- 1x SSR (soild state relay)

- 2x 1" tees

- 1x 1" hosetail

- 1x forecourt dispensing nozzle

- various cable ties, jubilee clips etc

Total cost @ 01/05/11 £425

- Click pictures to enlarge

Usage

Drying WVO

| Step | Lid | Heater | Pump | V1 | V2 | V3 | V4 | V5 | V6 | V7 | V8 | V9 | V10 | V11 | Notes |

| Oil in | Pour or pump oil into processor via the drum sieve. | ||||||||||||||

| Heat Oil | 65°C | Check the oil level. The element must be covered before switching on. | |||||||||||||

| Settle oil | Leave to settle for a minimum of 7 days. | ||||||||||||||

| Drain crud | Drain water and 'whites' until good oil is observed. | ||||||||||||||

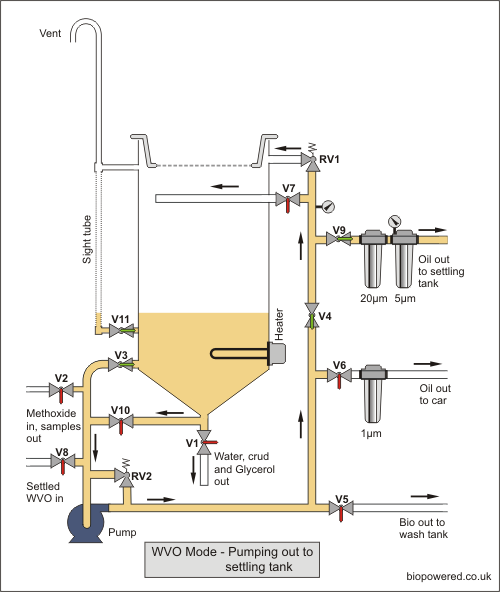

| Pump to settling tank |

Bio production

| Step | Lid | Heater | Pump | V1 | V2 | V3 | V4 | V5 | V6 | V7 | V8 | V9 | V10 | V11 | Notes |

| Oil in | Pour or pump oil into processor via the drum sieve. | ||||||||||||||

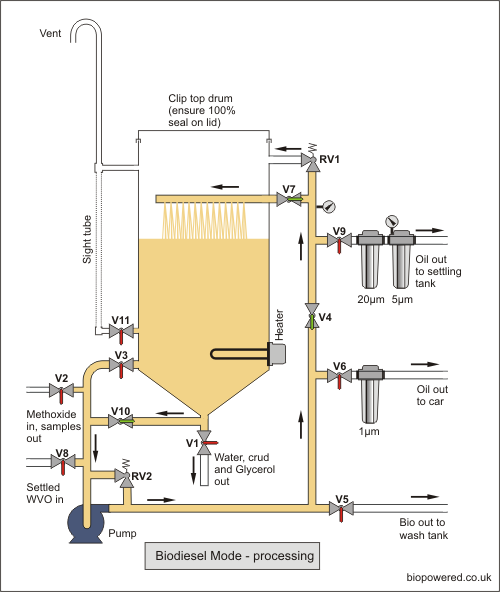

| Dry Oil | 65°C | Check the oil level. The element must be covered before switching on. Remove the drum sieve.Circulate oil until a 3/27 pass is achieved. | |||||||||||||

| Cool oil | Circulate oil until it reaches 65°C. Once at temperature, replace lid and ensure it makes and air tight seal. | ||||||||||||||

| Add Methoxide | With Methoxide container connected to V2, partially close V10 and crack open V2 to entrain Methoxide. On completion close V2 before fully opening V10 | ||||||||||||||

| Reaction satge | Run for 90 mins | ||||||||||||||

| 5% Prewash | Mix 15 mins. | ||||||||||||||

| Settle Glycerol | Wait 90 mins. | ||||||||||||||

| Drain Glycerol | Drain slowly to avoid vortex in tank. | ||||||||||||||

| Pump out to wash tank | Check heater is off before pumpig out. |

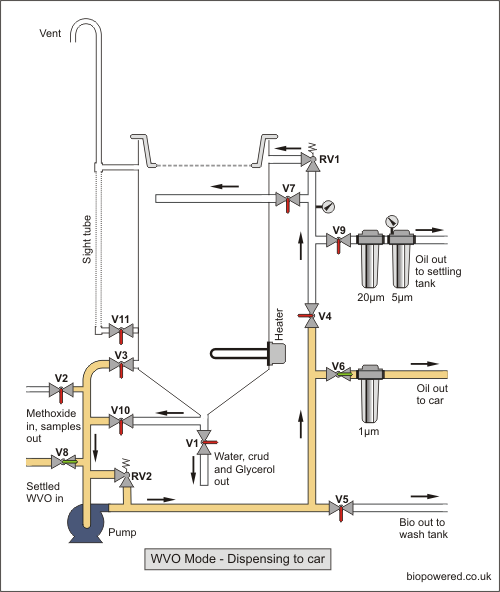

Dispensing WVO

| Step | Lid | Heater | Pump | V1 | V2 | V3 | V4 | V5 | V6 | V7 | V8 | V9 | V10 | V11 | Notes |

| Dispence settled oil | Lid can be on or off for this operation. |

The wvo goes into the drum via a 400 micron drum filter, it's then heated with the option of circulating to speed dewatering, it is then pumped into the storage drum via 20 and 5 micron filters. Most filters are rated at 0.8 bar so there is a bypass valve which ensures the oil is never forced through the filters. From the storage drum the oil goes through a 1 micron filter protected by the bottom bypass valve to the car/drums. A pipe and valve also connect the crud valve to the pump inlet so this can also be used to make biodiesel but it will need

an additional wet or dry wash tank. The methanol can be introduced before the pump and a pipe attached to the top of the sight tube

becomes the vent.

It will transfer to the wash/settling tank avoiding the filters and it utilises the clip top for sealing the processor.

An inline heater cannot be used with this design but an eductor or venturi could be added if desired along with a condensor but an additional vent outlet would need to be fitted to the lid.

You can dispense your wvo to the car/container via the delivery nozzle. When the trigger is released the oil is sent back to the tank by a bypass valve.

- Click pictures to enlarge

Safety Point

There is a float switch which cuts out the immersion heater at low oil level

Main Features

My aim was to make a self contained dual unit to which you can add extra storage drums/wash tank as needed but to also be affordable and portable. Also if either filter blocks the bypass valve will send the oil back into the main drum where it will just circulate in a loop. It is geared heavily towards filtering but can easily be used to process the unusable oil into bio

- Click pictures to enlarge

Footnote

- Click pictures to enlarge

Note: When useing this filter system (YOU MUST DROP WATER & FATS) after heating and before pumping out, if not you run the risk of emulsification with newly settled oil and the crud layer zone water/fats mixing up.

See also

KH 23:02, 13 June 2011 (BST)