Difference between revisions of "Processor pressure switch"

(First pass at pressure level swith page) |

(Added cat) |

||

| Line 35: | Line 35: | ||

[[File:Level_switch_circuit.png]] | [[File:Level_switch_circuit.png]] | ||

| + | [[Category:Biodiesel]] | ||

Revision as of 22:31, 8 January 2011

With processors that contain a heating element in the liquid, there is the risk of Methanol vapour explosion in the following circumstances:

- liquid level drops because of a leak while the processor is unattended

- leaving the element on when the processor is being drained

- turning on the element when the processor is empty

To reduce the risk it is sensible to fit a deadlock on the heater element to ensure that it cannot be switched on unless the element is completely submerged.

One way to do this is using a washing machine pressure switch. These can be picked up from most white goods repair shops or online.

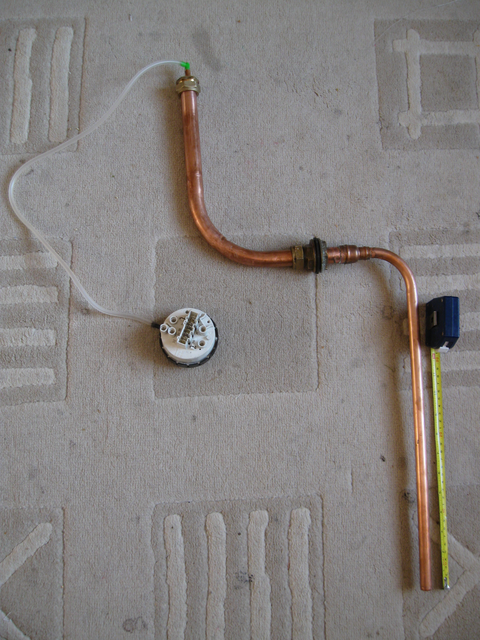

The pressure switch requires a tube down into the liquid inside the processor - this can either be through a port in the top of the processor or through a side port, as in this example:

The 15mm pipe by the tape measure pokes through a port in the side of the tank. The 22mm pipe is on the outside, and is long enough to prevent liquid escaping should there ever be an air leak from the flexible tubing or switch.

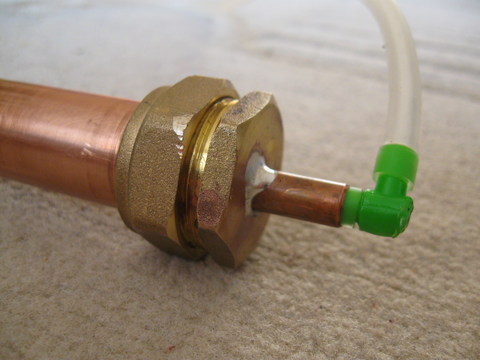

Here's the top, where the flexible tubing connects:

This is made from a 22mm end stop, with a hole drilled to fit one a little copper insert as used to reinforce plastic piping (the 10mm kind). It's soldered in place to make it air tight.

The green elbow is just an aquarium pipe connector - it squashes the very short length of aquarium tubing that goes inside the copper insert tightly against it's inner surface. The other side goes off to the pressure switch.

The end of the 15mm pipe should be dunked into water inside a squash bottle to test it for leaks and the trip points.

This pressure level switch has two trip points with hysteresis on both, measured from the end of the pipe underwater to the liquid surface. One was at 60mm (filling) 30mm (emptying), and one at 120mm (filling) and 90mm (emptying).

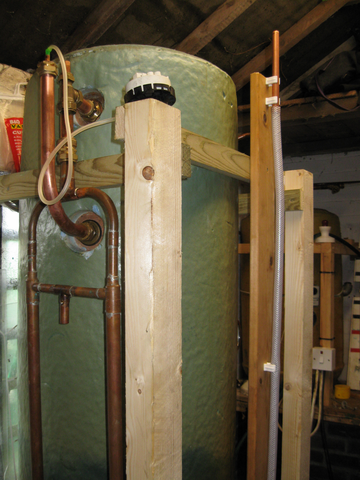

Here it is fitted to the processor (next to the condenser):

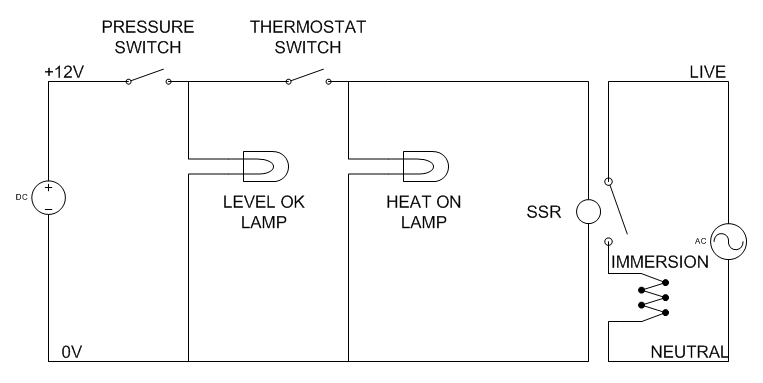

To control the immersion a relay is required, preferably a Solid State Relay. The switch side should be low voltage DC, say 9-12V as provided by many wall plug-in transformers.

Suggested circuit: