Difference between revisions of "Pump - TAM 120"

| Line 1: | Line 1: | ||

<metadesc>TAM120, Biodiesel processor pump, Biodiesel transfer pump, WVO pump, WVO transfer pump, TAM120 instruction manual, TAM 120 parts list</metadesc> | <metadesc>TAM120, Biodiesel processor pump, Biodiesel transfer pump, WVO pump, WVO transfer pump, TAM120 instruction manual, TAM 120 parts list</metadesc> | ||

| − | [[File:TAM120-New design.jpg|250px|thumb|right|TAM 120 centrifugal pump]] | + | [[File:TAM120-New design.jpg|250px|thumb|right|TAM 120 centrifugal pump - new design]] |

| − | + | [[File:TAM120-Old design.jpg|250px|thumb|right|TAM 120 centrifugal pump - old design]] | |

| Line 8: | Line 8: | ||

__TOC__ | __TOC__ | ||

| + | |||

| + | |||

| Line 36: | Line 38: | ||

* Motor Shaft Stainless steel | * Motor Shaft Stainless steel | ||

| + | ==TAM 120 problems and repairs== | ||

| + | [[File:TAM120 burnt capacitor.jpg|250px|thumb|right|TAM120 burnt out capacitor]] | ||

| − | + | [[File:TAM120 melted terminal block.jpg|250px|thumb|right|TAM120 melted terminal block]] | |

| − | + | [[File:TAM 120 wiring dia.png|250px|thumb|right|TAM120 wiring diagram]] | |

| + | [[File:TAM120 new capacitor.jpg|250px|thumb|right|TAM120 "hard wired" with a replacement capacitor]] | ||

| − | |||

| + | Whilst the major mechanical components have proved rugged in service, several examples of terminal boxes cracking and capacitors over heating with subsequent damage to the terminal block have been observed. These issues can be easily remedied using replacement items: see [3D Printed parts and spares]for a stronger design of 3D printed terminal box or replace with a suitable electrical junction box. | ||

| + | Suitable capacitors can be readily acquired from on line auction sites. Original capacitor specification was 40µF ±5%, 450V AC, 50/60Hz. The replacement capacitor must be suitable for continuous duty. | ||

| + | Where the capacitor has melted the terminal block, it's possible to "hard wire" a new capacitor according to the diagram, right. Ensure that suitable insulation is present at all new electrical connections and if in any doubt seek the advise of a qualified electrician. | ||

| − | + | On later TAM120 the terminal box and capacitor location was altered (as per photo top right of this page), presumably to overcome these issues. | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

Revision as of 22:05, 9 April 2015

The TAM120 peripheral pump is sold as being compatible with both mineral diesel and biodiesel and suitable for liquid temperatures up 90°C. This coupled with a good performance make it well suited to a small to medium size home processor, although note should be made of the maximum particle size the pump is able to handle.

TAM 120 specifications

- Voltage 230v

- Frequency 50Hz

- Power 1.5KW

- Speed 2800RPM

- Duty cycle Continuous

- Max flow 80lpm @ 0m head

- Max pressure 7.5 Bar

- Max suction lift 7 m

- Inlet 1½" BSP male

- Outlet fitting 1½" BSP male

- Max particle tolerance 100 Micron

- Max liquid temp 90°C

Components

- Pump Body Cast iron (Painted)

- Impeller Case Cast iron (Painted)

- Impeller Case Seal NBR

- Motor Shaft Seal NBR

- Impeller Brass

- Shaft Key and Nut Stainless steel

- Motor Shaft Stainless steel

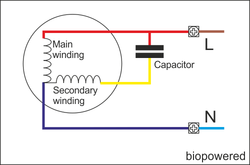

TAM 120 problems and repairs

Whilst the major mechanical components have proved rugged in service, several examples of terminal boxes cracking and capacitors over heating with subsequent damage to the terminal block have been observed. These issues can be easily remedied using replacement items: see [3D Printed parts and spares]for a stronger design of 3D printed terminal box or replace with a suitable electrical junction box.

Suitable capacitors can be readily acquired from on line auction sites. Original capacitor specification was 40µF ±5%, 450V AC, 50/60Hz. The replacement capacitor must be suitable for continuous duty.

Where the capacitor has melted the terminal block, it's possible to "hard wire" a new capacitor according to the diagram, right. Ensure that suitable insulation is present at all new electrical connections and if in any doubt seek the advise of a qualified electrician.

On later TAM120 the terminal box and capacitor location was altered (as per photo top right of this page), presumably to overcome these issues.