Difference between revisions of "Melting stick"

(→First heading here) |

|||

| (22 intermediate revisions by 3 users not shown) | |||

| Line 1: | Line 1: | ||

| − | |||

| − | |||

<metadesc>Solid oil melting stick</metadesc> | <metadesc>Solid oil melting stick</metadesc> | ||

| + | [[File:Melting_stick_2.jpg|450px|thumb|right|Completed Melting stick. Source K.H]] | ||

| + | This is a useful, easily made item used to melt solid oil, palm oil, glycerine and whites. | ||

| + | <br> | ||

| + | <br> | ||

| − | + | __TOC__ | |

| − | + | <br> | |

| − | + | <br> | |

| − | |||

| − | |||

| − | |||

| + | ==Overview== | ||

| + | The melting stick is constructed using a 220-240 volt cartridge heater. These are readily available from on-line auction sites and other outlets. The heaters are available in 110v and 230v versions and are offered in a range of Wattages from 150W to 600W. | ||

| + | The unit described here is based on a 300W unit, a size which has proved satisfactory for melting volumes of 20 litres and greater. The design of the "tosser tube" is sufficiently compact to fit through screw top lids of plastic cubies and 20 litre tins. | ||

| − | + | <br> | |

| − | + | <br> | |

| + | <br> | ||

| + | <br> | ||

| + | <blockquote style="background-color: lightgrey; border: solid thin grey;"> | ||

| + | Although known by some low lifes as a tosser tube it is really a modern red hot poker and can be demonstrated on said low life! | ||

| + | </blockquote> | ||

| + | ::Quote source: K.H | ||

| − | + | <br> | |

| − | + | <br> | |

| − | + | <br> | |

| − | + | <br> | |

| − | == | + | ==Components== |

| − | |||

| − | |||

| − | |||

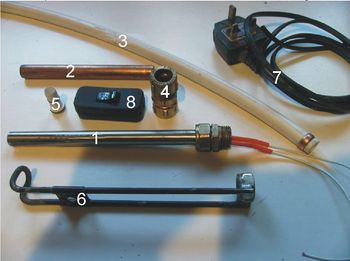

| − | + | [[File:Melting stick components.jpg|350px|thumb|left|Components used. Source K.H]] | |

| + | [[File:Electrics.jpg |350px|thumb|center|Electrical connections. Source K.H]] | ||

| + | <br> | ||

| + | <br> | ||

| − | + | # ... 1 off ... cartridge heater 15mm outside diamater, 300W (available in various wattages) | |

| + | # ... 1 off ... short length of 15mm copper pipe | ||

| + | # ... 2ft ... 15mm plastic pipe | ||

| + | # ... 2 off ... 15mm - 15mm straight compression fitting | ||

| + | # ... 1 off ... plastic pipe insert | ||

| + | # ... 1 off ... Stand-off (piece of metal slightly longer than the heater with the end bent over) | ||

| + | # ... 1 off ... cable and plug | ||

| + | # ... 1 off ... in line power switch | ||

| + | # ... 2 off ... insulated crimp connectors | ||

| + | # ... 2 off ... shrink sleeving | ||

| + | # ... 1 off ... Gp7 brass cable gland | ||

| + | <br> | ||

| + | <br> | ||

| + | <br> | ||

| − | === | + | ==Assembly== |

| − | |||

| − | |||

| − | |||

| − | + | Solder the stand-off to a compression nut. This is to keep the heater away from the container walls and the curl at the end prevents contact with the container bottom. | |

| − | + | Connect the heater cable tails to the power cable by soldering and insulating with the heat-shrink, ensuring that the sleeve is securely attached and cannot slide away from the joint. Alternatively crimp connectors can be employed and, for additional safety, can be covered with heat-shrink sleeveing. Cutting one heater cable tail slightly shorter than the other, will ensure the joints are staggered making it easer to insert the cabling into the tube. | |

| − | |||

| − | |||

| + | Tighten the heater into a straight 15 mm compression fitting using the nut with the stand off attached, then attach the copper 15 mm copper pipe to the other end of the fitting, feeding the cable through the pipe as it's assembled. The copper pipe needs to be long enough to prevent the plastic pipe from becoming too hot. | ||

| − | + | Attach the second 15 mm compression fitting to the other end of the copper pipe, by carefully threading onto the cable. Feed the cable through the pipe insert and the plastic pipe, and tighten the second compression fitting. | |

| − | |||

| − | |||

| + | Disassemble the cable gland and slide over the cable. The pipe ID is the correct tapping size for the gland thread. If a chamfer is put on the inside of the pipe, it should be possible to screw the gland into position, the metal forming a thread as it's screwed in (warming the pipe may assit in this procedure). Take care not to wind up the cable as you install the gland body, or fit the gland before threading onto the cable. | ||

| − | + | Assemble the rest of the gland, ensuring that the cable is slack within the pipe and gripped satisfactorily so it anchors the cable if pulled. | |

| − | |||

| − | + | A suitably rated inline switch fitted to the cable makes for easier operation. | |

| + | <br> | ||

| + | <br> | ||

| − | + | <gallery widths="250px" heights="200px" perrow="3" align="center"> | |

| + | File:Melting_stick_0013.jpg|15mm dia, 300W cartridge heater. Source: K.H | ||

| + | File:Melting_stick_001.jpg|Completed melting stick. Source: K.H | ||

| + | File:Melting_stick_006.jpg|Melting stick in action. Source: K.H | ||

| + | </gallery> | ||

| + | {{#ev:youtube|Hn6a_ZrMBfw|400|center|Melting stick in action. Source: K.H}} | ||

| + | <br> | ||

| + | <br> | ||

| + | <br> | ||

| + | <br> | ||

| + | <br> | ||

| + | <br> | ||

| − | |||

==See also== | ==See also== | ||

| − | |||

| − | |||

| − | |||

| − | |||

| + | [[User:KH|KH]] 22:44, 27 October 2012 (BST) | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | [[Category:Biodiesel]] | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | [[Category: | ||

| − | |||

| − | |||

[[Category:Processors and equipment]] | [[Category:Processors and equipment]] | ||

| − | [[Category: | + | [[Category:Vegetable oil]] |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

[[Category:Filtration & drying equipment]] | [[Category:Filtration & drying equipment]] | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

Latest revision as of 11:27, 1 March 2013

This is a useful, easily made item used to melt solid oil, palm oil, glycerine and whites.

Contents

Overview

The melting stick is constructed using a 220-240 volt cartridge heater. These are readily available from on-line auction sites and other outlets. The heaters are available in 110v and 230v versions and are offered in a range of Wattages from 150W to 600W.

The unit described here is based on a 300W unit, a size which has proved satisfactory for melting volumes of 20 litres and greater. The design of the "tosser tube" is sufficiently compact to fit through screw top lids of plastic cubies and 20 litre tins.

Although known by some low lifes as a tosser tube it is really a modern red hot poker and can be demonstrated on said low life!

- Quote source: K.H

Components

- ... 1 off ... cartridge heater 15mm outside diamater, 300W (available in various wattages)

- ... 1 off ... short length of 15mm copper pipe

- ... 2ft ... 15mm plastic pipe

- ... 2 off ... 15mm - 15mm straight compression fitting

- ... 1 off ... plastic pipe insert

- ... 1 off ... Stand-off (piece of metal slightly longer than the heater with the end bent over)

- ... 1 off ... cable and plug

- ... 1 off ... in line power switch

- ... 2 off ... insulated crimp connectors

- ... 2 off ... shrink sleeving

- ... 1 off ... Gp7 brass cable gland

Assembly

Solder the stand-off to a compression nut. This is to keep the heater away from the container walls and the curl at the end prevents contact with the container bottom.

Connect the heater cable tails to the power cable by soldering and insulating with the heat-shrink, ensuring that the sleeve is securely attached and cannot slide away from the joint. Alternatively crimp connectors can be employed and, for additional safety, can be covered with heat-shrink sleeveing. Cutting one heater cable tail slightly shorter than the other, will ensure the joints are staggered making it easer to insert the cabling into the tube.

Tighten the heater into a straight 15 mm compression fitting using the nut with the stand off attached, then attach the copper 15 mm copper pipe to the other end of the fitting, feeding the cable through the pipe as it's assembled. The copper pipe needs to be long enough to prevent the plastic pipe from becoming too hot.

Attach the second 15 mm compression fitting to the other end of the copper pipe, by carefully threading onto the cable. Feed the cable through the pipe insert and the plastic pipe, and tighten the second compression fitting.

Disassemble the cable gland and slide over the cable. The pipe ID is the correct tapping size for the gland thread. If a chamfer is put on the inside of the pipe, it should be possible to screw the gland into position, the metal forming a thread as it's screwed in (warming the pipe may assit in this procedure). Take care not to wind up the cable as you install the gland body, or fit the gland before threading onto the cable.

Assemble the rest of the gland, ensuring that the cable is slack within the pipe and gripped satisfactorily so it anchors the cable if pulled.

A suitably rated inline switch fitted to the cable makes for easier operation.

See also

KH 22:44, 27 October 2012 (BST)