Difference between revisions of "Diffuser"

(→Basic drying method) |

|||

| (9 intermediate revisions by 4 users not shown) | |||

| Line 12: | Line 12: | ||

==Basic drying method== | ==Basic drying method== | ||

{{#ev:youtube| Bv8ivoE7lXQ?fs=1&hl=en_GB |300|right|Diffuser cone used for drying oil. Source: K.H}} | {{#ev:youtube| Bv8ivoE7lXQ?fs=1&hl=en_GB |300|right|Diffuser cone used for drying oil. Source: K.H}} | ||

| + | [[File: Diffuser.jpg|250px|thumb|left|Diffuser for 2" pipework. Source: K.H]] | ||

| − | Early drying methods for oil and biodiesel typically comprised of a tank, a circulating pump with associated pipe work and a sparge pipe which squirted streams of liquid through the air within the open top of the tank. The aim of this process was to gain as much contact between the air and the hot | + | |

| + | Early drying methods for oil and biodiesel typically comprised of a tank, a circulating pump with associated pipe work and a sparge pipe which squirted streams of liquid through the air within the open top of the tank. The aim of this process was to gain as much contact between the air and the hot biodiesel or oil as possible, so that any suspended water could evaporate. | ||

| + | <br> | ||

| + | <br> | ||

<br> | <br> | ||

<br> | <br> | ||

| Line 27: | Line 31: | ||

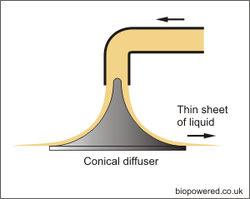

==Conical diffuser== | ==Conical diffuser== | ||

| − | [[File: Diffuser cone.png| | + | [[File: Diffuser cone.png|250px|thumb|left|Ideal profile for a diffuser]] |

| + | [[File: Jamesrldiffuser.jpg|300px|thumb|right|Conical diffuser. Source jamesrl.]] | ||

| − | Logically, increasing the surface area of the liquid whilst in the air will result in improved efficiency, so some home brewers use diffusers to achieve this. The ideal shape is a cone with concave sides but this is difficult to manufacture without suitable tools. Straight sided cones are easer to manufacture, work almost as well and are far more efficient | + | Logically, increasing the surface area of the liquid whilst in the air will result in improved efficiency, so some home brewers use diffusers to achieve this. The ideal shape is a cone with concave sides but this is difficult to manufacture without suitable tools. Straight sided cones are easer to manufacture, work almost as well and are far more efficient than the sparge pipe arrangement. |

| + | <br> | ||

| + | <br> | ||

| + | <br> | ||

| + | <br> | ||

| + | <br> | ||

<br> | <br> | ||

<br> | <br> | ||

| Line 39: | Line 49: | ||

<br> | <br> | ||

<br> | <br> | ||

| − | |||

==The Uri Geller diffuser== | ==The Uri Geller diffuser== | ||

| − | A particularly inventive idea comes from Uberveg | + | A particularly inventive idea comes from Uberveg. Construction time must have been all of 90 seconds and needs no description! |

<br> | <br> | ||

<br> | <br> | ||

| − | <gallery caption="Ingenious use of | + | <gallery caption="Ingenious use of soup spoons and ladles as diffusers." widths="400px" heights="280px" perrow="2"> |

File: Spoon_diffuser_1_-_Uberveg.jpg|A vertical Uri. Source: Uberveg | File: Spoon_diffuser_1_-_Uberveg.jpg|A vertical Uri. Source: Uberveg | ||

File: Spoon_diffuser_2_-_Uberveg.jpg|A horizontal Uri. Source: Uberveg | File: Spoon_diffuser_2_-_Uberveg.jpg|A horizontal Uri. Source: Uberveg | ||

| + | File:Ladle_diffuser.jpg|An appropriately adjusted ladle. Source: Rossey | ||

</gallery> | </gallery> | ||

| + | |||

| + | |||

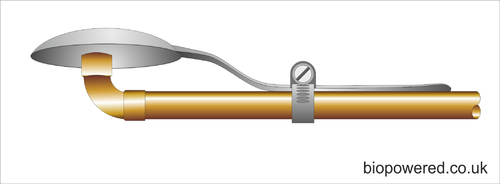

| + | ==The inverted Uri diffuser== | ||

| + | [[File:Inverted spoon diffuser.png|500px|thumb|right|Inverted Uri constructed from an old spoon and a hose clip mounted over a vertical elbow on the pipe.]] | ||

| + | Since the Uri Geller diffuser was made, huntman40 has come up with a rather simple and effective modification, the inverted Uri. It's construction should will be obvious from the graphic. It would appear that this arrangement while producing an improved spray pattern, also reduces splashing. | ||

| + | |||

| + | {{#ev:youtube| 5orLlfnbxZs|400|left|A extremely effective inverted Uri. Source: huntman40}} | ||

| + | |||

| + | <br> | ||

| + | <br> | ||

| + | <br> | ||

| + | <br> | ||

| + | <br> | ||

| + | <br> | ||

| + | <br> | ||

| + | <br> | ||

| + | <br> | ||

| + | <br> | ||

| + | <br> | ||

| + | <br> | ||

| + | <br> | ||

| + | <br> | ||

| + | <br> | ||

| + | <br> | ||

| + | <br> | ||

| + | <br> | ||

| + | <br> | ||

Latest revision as of 22:45, 28 February 2013

A diffuser is a simple device used to improve efficiency when air drying used cooking oil or biodiesel.

Contents

Basic drying method

Early drying methods for oil and biodiesel typically comprised of a tank, a circulating pump with associated pipe work and a sparge pipe which squirted streams of liquid through the air within the open top of the tank. The aim of this process was to gain as much contact between the air and the hot biodiesel or oil as possible, so that any suspended water could evaporate.

Conical diffuser

Logically, increasing the surface area of the liquid whilst in the air will result in improved efficiency, so some home brewers use diffusers to achieve this. The ideal shape is a cone with concave sides but this is difficult to manufacture without suitable tools. Straight sided cones are easer to manufacture, work almost as well and are far more efficient than the sparge pipe arrangement.

The Uri Geller diffuser

A particularly inventive idea comes from Uberveg. Construction time must have been all of 90 seconds and needs no description!

- Ingenious use of soup spoons and ladles as diffusers.

The inverted Uri diffuser

Since the Uri Geller diffuser was made, huntman40 has come up with a rather simple and effective modification, the inverted Uri. It's construction should will be obvious from the graphic. It would appear that this arrangement while producing an improved spray pattern, also reduces splashing.

Bio-rich-time-poor 01:56, 18 January 2011 (UTC)