Difference between revisions of "Processor build step by step"

| (7 intermediate revisions by the same user not shown) | |||

| Line 1: | Line 1: | ||

<metadesc>Biodiesel processor build step by step.</metadesc> | <metadesc>Biodiesel processor build step by step.</metadesc> | ||

| − | |||

| − | |||

| − | |||

| − | |||

| Line 12: | Line 8: | ||

__TOC__ | __TOC__ | ||

| + | |||

| Line 21: | Line 18: | ||

===Settings, Wire and Gas=== | ===Settings, Wire and Gas=== | ||

| − | Welding thin metal is much harder than welding thick chucks of framework. If you have limited experience welding thin steel (like the author) then practice of some offcuts and make sure you can get a | + | Welding thin metal is much harder than welding thick chucks of framework. If you have limited experience welding thin steel (like the author) then practice of some offcuts and make sure you can get a neat weld. If it looks tidy and flat then it is far more likely to seal. If the welding isn't going well then there is something wrong, don't keep piling on the weld as it is very unlikely to seal. Try any of the following: |

| − | + | Changing the power setting | |

Changing the feed rate | Changing the feed rate | ||

| Line 38: | Line 35: | ||

| − | If you are putting holes in the steel sheet and have tried all of the above, it might be that your welder does not have a low enough setting for such thin | + | If you are putting holes in the steel sheet and have tried all of the above, it might be that your welder does not have a low enough setting for such thin steel, in which case use the "on, off" technique. Weld for a few seconds then let off for a second and restart, this gives the sheet just long enough to cool in the gaps so that a hole does not appear. Again this needs practice before starting on the drum. |

| − | The cone in this article was welded with 0.8mm wire and a CO[sup] | + | The cone in this article was welded with 0.8mm wire and a CO[sup]2[/sup] shield gas. It was not easy! It was a miracle that it didn't leak. The better combination was 0.6mm wire and a proportion of argon gas. The author used 100% argon although others might recommend a mix. The exact gas is outside of the scope of this article. |

| Line 48: | Line 45: | ||

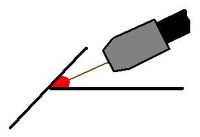

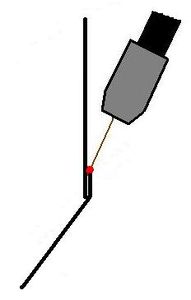

It was initially thought that a fillet weld was a good idea as in the illustration below. However advice from the forum and experience while tacking the cone to the drum both proved this was a bad idea. | It was initially thought that a fillet weld was a good idea as in the illustration below. However advice from the forum and experience while tacking the cone to the drum both proved this was a bad idea. | ||

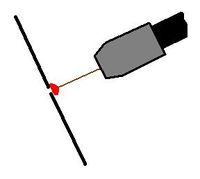

| − | A butt welded joint is neat if you can pull it off. It is a very difficult joint to get right as the two sheets of metal need to meet all the way along the joint with no significant gap. With a joint like this it is very easy to make holes. | + | A butt welded joint is neat if you can pull it off. It is a very difficult joint to get right as the two sheets of metal need to meet all the way along the joint with no significant gap. With a joint like this it is very easy to make holes. This method is not recommended unless you are an experienced welder. |

| + | |||

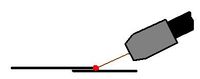

| + | A lap joint is by far the easiest joint to go with. The cone in the this article was attached to the barrel with a welded lap joint. It was easily done and sealed well (only 3 minor leaks). This joint is easily done as there is more material to disperse the heat (hence harder to make holes) and its much easier to get the two sheets close together with no gaps (just hammer them together). | ||

| − | |||

<gallery caption="Welded joints" widths="200px" heights="300px" perrow="4" align="left"> | <gallery caption="Welded joints" widths="200px" heights="300px" perrow="4" align="left"> | ||

| − | File:Fillet Joint.jpg|This was fine for tacking the cone in place (see below) but is not suitable for a sealed | + | File:Fillet Joint.jpg|This was fine for tacking the cone in place (see below) but is not suitable for a sealed joint. |

File:Butt Joint.jpg|This is very difficult to do without putting holes in the sheet, so it is recommended to avoid this type of joint. | File:Butt Joint.jpg|This is very difficult to do without putting holes in the sheet, so it is recommended to avoid this type of joint. | ||

| − | File:Lap Joint.jpg|This is the easiest joint for | + | File:Lap Joint.jpg|This is the easiest joint for a novice welder (like the author), the least likely to make holes, and the most likely to seal. |

</gallery> | </gallery> | ||

| Line 66: | Line 64: | ||

| − | <gallery caption="" widths="200px" heights="300px" perrow="4" align="left"> | + | <gallery caption="The Barrel" widths="200px" heights="300px" perrow="4" align="left"> |

File:20140325 195201.jpg|The Barrel when it was bought, the membrane was not in place, the clip was included but not photographed. | File:20140325 195201.jpg|The Barrel when it was bought, the membrane was not in place, the clip was included but not photographed. | ||

| − | File:20140325 195323.jpg|Cut the bottom off the barrel leaving a little of the curved edge intact. This will mean the cone needs less shaping (hammering) to fit the profile of the barrel. | + | File:20140325 195323.jpg|Cut the bottom off the barrel leaving a little of the curved edge intact. This will mean the cone needs less shaping (hammering) to fit the profile of the barrel (see below). |

| − | File:20140325 195345.jpg|Remove all of the paint from the area where welding will take place. It might be a good idea to remove paint from the inside surface too, | + | File:20140325 195345.jpg|Remove all of the paint from the area where welding will take place. It might be a good idea to remove paint from the inside surface too, the gasses released from the burning paint can interfere with the welding. |

</gallery> | </gallery> | ||

| Line 89: | Line 87: | ||

There is no harm in making the cone bigger than it has to be and trimming it back later. In fact this is important to the welding method used in this write up. | There is no harm in making the cone bigger than it has to be and trimming it back later. In fact this is important to the welding method used in this write up. | ||

| − | Leave the hole in the middle of the cone smaller than you intend, until the cone is welded up. You might have the right size hole as per the calculations, but it is easy to make that hole the wrong the shape when you | + | Leave the hole in the middle of the cone smaller than you intend, until the cone is welded up. You might have the right size hole as per the calculations, but it is easy to make that hole the wrong the shape when you are forming the curve of the cone and welding. |

| − | |||

| − | |||

| − | |||

| − | <gallery caption="" widths="200px" heights="300px" perrow="4" align="left"> | + | <gallery caption="The Cone" widths="200px" heights="300px" perrow="4" align="left"> |

| − | File:20140323 120641.jpg|After much looking around for sheet steel it was decided the back of this cupboard was suitable so it was marked up and cut out. | + | File:20140323 120641.jpg|After much looking around for sheet steel it was decided that the back of this cupboard was suitable, so it was marked up and cut out. |

File:20140323 133719.jpg|The cone was welded on the inside and the outside to give a better chance of sealing. | File:20140323 133719.jpg|The cone was welded on the inside and the outside to give a better chance of sealing. | ||

File:20140411 190745.jpg|Once the cone is welded up, cut the hole in the bottom of the cone to the right size. You can carefully use a hole saw or a dye grinder. Then weld the nipple in place. The size of the nipple depends on your choice of pump. | File:20140411 190745.jpg|Once the cone is welded up, cut the hole in the bottom of the cone to the right size. You can carefully use a hole saw or a dye grinder. Then weld the nipple in place. The size of the nipple depends on your choice of pump. | ||

</gallery> | </gallery> | ||

| − | |||

| − | |||

| Line 110: | Line 103: | ||

| + | ==Attaching the Cone and Drum== | ||

| + | If you've got this far then the welding is no more complex than the welding involved in making the cone, just a little more of it. The method used here was to mount the cone in a vice and place the barrel on top. By pushing down on the barrel, the bottom of the barrel and the top of the cone are forced to take up the same shape and any gaps between the two disappear. At this point the two can be tack welded together. Using many tack welds will serve to hold the shape better but then there are more tack welds to remove as you complete the permanent weld. Anything between 8 and 12 is fine. A fillet weld is fine at this time as it is only to hold the barrel in place and hammering the edge of the cone would be very difficult before the two are attached. | ||

| + | When the barrel is suitably located take the assembly down and weld on the bench. At this point use a small hammer to bend the edge of the cone down to sit flush against the barrel for a welded lap joint. Hammer an inch or two flat at a time, weld and repeat. When you get close to a tack weld, you'll need to grind out the tack weld so that you can continue with the hammering and welding (i,e. so the lap joint is continuous). | ||

| − | Welding | + | <gallery caption="Attaching the cone" widths="200px" heights="300px" perrow="4" align="left"> |

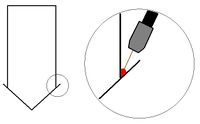

| − | + | File:Welding.JPG|This is suitable only for holding the cone to the barrel and is not a suitable weld for sealing. | |

| − | + | File:20140411 194606.jpg|This photograph gives an idea of how much edge is needed. This was a suitable amount for the tack welds and enough to hammer flat without creating ripples. | |

| − | + | File:Weldinglap.JPG|Once the cone is held in place hammer the edge of the cone flat as seen here and proceed to weld the lap joint. | |

| − | + | File:20140411 204057.jpg|This Photograph shows a tack weld that has just been removed and hammered flat, this is about to be welded. | |

| − | + | File:20140411 210357.jpg|Eventually you'll get to the finished item. | |

| − | + | File:20140417 094936.jpg|The valve is essential for testing the welds | |

| − | + | File:20140417 094903.jpg|Time to start thinking about mounting options | |

| − | + | </gallery> | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | < | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | At this point it is highly recommended that you fit a ball valve on the bottom and test for leaks. In the case of a leak, grind the weld back and try again. When all of the welds are sealed up apply some paint (to the outside) to stop corrosion. | |

| − | |||

| − | |||

| + | If you have got a processor tank to this stage of completion then you have reached a major mile stone. Next you'll need to think about an immersion heater flange and all the additions to the top of the tank, then how you will mount the tank. See links below. | ||

| − | |||

| Line 223: | Line 130: | ||

| − | |||

==See also== | ==See also== | ||

| − | + | * http://www.biopowered.co.uk/wiki/Cone_bottoms_for_tanks | |

| − | + | * http://www.biopowered.co.uk/wiki/Fitting_a_heater_flange | |

| − | |||

| − | * | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

==Further reading== | ==Further reading== | ||

| − | + | * http://www.biopowered.co.uk/wiki/Importance_of_venting_a_processor | |

| + | * http://www.biopowered.co.uk/wiki/Diffuser | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | By Laurence (lozzzzzz on BioPowered Forum) April 2014 | |

| − | + | [[Category:Biodiesel]] | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | [[Category: | ||

| − | |||

| − | |||

[[Category:Processors and equipment]] | [[Category:Processors and equipment]] | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

Latest revision as of 09:23, 18 April 2014

There are a number of ways you can get hold of, or make a tank. This page describes how a tank can be made using a 44 gallon drum and a home made come.

Contents

Welding Considerations

Settings, Wire and Gas

Welding thin metal is much harder than welding thick chucks of framework. If you have limited experience welding thin steel (like the author) then practice of some offcuts and make sure you can get a neat weld. If it looks tidy and flat then it is far more likely to seal. If the welding isn't going well then there is something wrong, don't keep piling on the weld as it is very unlikely to seal. Try any of the following:

Changing the power setting

Changing the feed rate

Make sure there is enough shield gas

Cleaning out the end of the gun

Changing the tip.

Check you are using an appropriate wire thickness.

Check you are using an appropriate shield gas.

If you are putting holes in the steel sheet and have tried all of the above, it might be that your welder does not have a low enough setting for such thin steel, in which case use the "on, off" technique. Weld for a few seconds then let off for a second and restart, this gives the sheet just long enough to cool in the gaps so that a hole does not appear. Again this needs practice before starting on the drum.

The cone in this article was welded with 0.8mm wire and a CO[sup]2[/sup] shield gas. It was not easy! It was a miracle that it didn't leak. The better combination was 0.6mm wire and a proportion of argon gas. The author used 100% argon although others might recommend a mix. The exact gas is outside of the scope of this article.

Welded joint types

It was initially thought that a fillet weld was a good idea as in the illustration below. However advice from the forum and experience while tacking the cone to the drum both proved this was a bad idea.

A butt welded joint is neat if you can pull it off. It is a very difficult joint to get right as the two sheets of metal need to meet all the way along the joint with no significant gap. With a joint like this it is very easy to make holes. This method is not recommended unless you are an experienced welder.

A lap joint is by far the easiest joint to go with. The cone in the this article was attached to the barrel with a welded lap joint. It was easily done and sealed well (only 3 minor leaks). This joint is easily done as there is more material to disperse the heat (hence harder to make holes) and its much easier to get the two sheets close together with no gaps (just hammer them together).

- Welded joints

Preparing the Barrel

Steel Barrels have either a solid top with a small cap or a fully removable lid with a band around the top to seal it. This depends on what the barrel was originally intended to do. Most liquids usually have a small cap with the clip top barrels typically used for powder products. Both are readily available. The barrel pictured here originally contained fruit juice but had a membrane inside so a "clip top" barrel was used. This barrel cost the author £10 and as a result of the membrane has no corrosion inside.

- The Barrel

Preparing the cone

This section is brief as there is a wiki page specifically for making a cone. If you are using this write-up and making your own processor tank you will need to visit the following page for the specifics on making a cone:

http://www.biopowered.co.uk/wiki/Cone_bottoms_for_tanks

It is worth considering these extra points in addition to the information found in the cone wiki page:

The barrel is made from 0.8mm sheet steel so it would be sensible to find some sheet of the same thickness for making the cone.

It might be worth adding a tab to the straight edge of the cone to help with welding it up.

There is no harm in making the cone bigger than it has to be and trimming it back later. In fact this is important to the welding method used in this write up.

Leave the hole in the middle of the cone smaller than you intend, until the cone is welded up. You might have the right size hole as per the calculations, but it is easy to make that hole the wrong the shape when you are forming the curve of the cone and welding.

- The Cone

With a suitable size ball valve fitted you can mount the assembly in a vice, add water and check for leaks. You will need to check for leaks after attaching the cone to the barrel, however it is a good idea to check the cone at this point as it is much easier to repair when not attached to the barrel.

Attaching the Cone and Drum

If you've got this far then the welding is no more complex than the welding involved in making the cone, just a little more of it. The method used here was to mount the cone in a vice and place the barrel on top. By pushing down on the barrel, the bottom of the barrel and the top of the cone are forced to take up the same shape and any gaps between the two disappear. At this point the two can be tack welded together. Using many tack welds will serve to hold the shape better but then there are more tack welds to remove as you complete the permanent weld. Anything between 8 and 12 is fine. A fillet weld is fine at this time as it is only to hold the barrel in place and hammering the edge of the cone would be very difficult before the two are attached.

When the barrel is suitably located take the assembly down and weld on the bench. At this point use a small hammer to bend the edge of the cone down to sit flush against the barrel for a welded lap joint. Hammer an inch or two flat at a time, weld and repeat. When you get close to a tack weld, you'll need to grind out the tack weld so that you can continue with the hammering and welding (i,e. so the lap joint is continuous).

- Attaching the cone

At this point it is highly recommended that you fit a ball valve on the bottom and test for leaks. In the case of a leak, grind the weld back and try again. When all of the welds are sealed up apply some paint (to the outside) to stop corrosion.

If you have got a processor tank to this stage of completion then you have reached a major mile stone. Next you'll need to think about an immersion heater flange and all the additions to the top of the tank, then how you will mount the tank. See links below.

See also

- http://www.biopowered.co.uk/wiki/Cone_bottoms_for_tanks

- http://www.biopowered.co.uk/wiki/Fitting_a_heater_flange

Further reading

- http://www.biopowered.co.uk/wiki/Importance_of_venting_a_processor

- http://www.biopowered.co.uk/wiki/Diffuser

By Laurence (lozzzzzz on BioPowered Forum) April 2014