Difference between revisions of "Plumbers delight condenser"

(Created page with "The 'Plumber's Delight' Condenser is aptly named as it uses all commonly available plumbing pipe and fittings. A Basic Plumber's delight' or P.D. for short is a one metre length...") |

|||

| (10 intermediate revisions by 4 users not shown) | |||

| Line 1: | Line 1: | ||

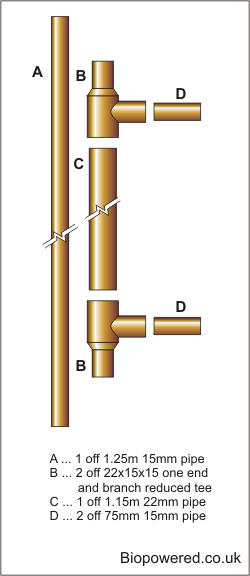

| − | + | [[File:PD components list.png|300px|thumb|right|Plumbers delight component parts]] | |

| − | + | The 'Plumber's delight' or PD condenser uses commonly available plumbing pipe and fittings, typically | |

| + | a one metre length of 22mm copper pipe with a 15mm copper pipe inside it. | ||

| − | + | __TOC__ | |

| − | |||

| − | + | ==Construction== | |

| + | 22 to 15 unequal tees are used at each end to seal the inner 15mm to the outer 22mm and allow water to be passed in the gap between the two pipes, forming a water jacket around the 15mm pipe. | ||

| − | + | Before fitting the tees the stops need to be removed to allow the 15mm pipe to pass through the fittings, and then the fittings soldered to the two pipes. | |

| + | |||

| + | Before assembly, the 15mm pipe is partially crimped at every inch or so. Each crimp should be at right-angles to the crimp before it, so as to create a turbulent vapour flow down the length of pipe and increase condensing efficiency. | ||

| + | |||

| + | ==Sizing and coolant== | ||

| + | |||

| + | A PD condenser that is one metre long will just about keep up with a 3kW heat source when used for methanol recovery, providing the coolant water flow is adequate and is kept below 20°C. | ||

| + | |||

| + | Water should be pumped into the bottom of the condenser and returned from the top - the opposite way to the top-to-bottom flow of the hot vapour. | ||

| + | |||

| + | As a rough guide, there needs to be at least as much condenser water as there is oil in the batch. | ||

| + | |||

| + | ===Vegetable oil as coolant=== | ||

| + | |||

| + | You might be thinking, "can I use the heat from the condenser to warm the oil for the next batch?". | ||

| + | |||

| + | Yes and no. Vegetable oil is not a good medium for heat transfer, as (due to it's specific heat capacity and density) it is 2.4 times less able to absorb heat vs. the same volume of water. | ||

| + | |||

| + | However, this useful heat may be recovered using another heat exchanger, using the warm water to heat your settling oil. | ||

| + | |||

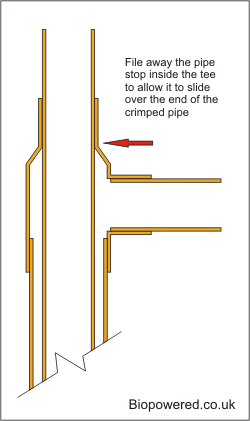

| + | [[File:PD pipe stop.png|300px|thumb|right|Assembly details]] | ||

| + | |||

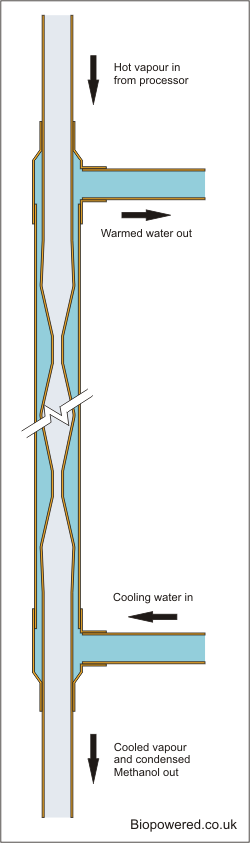

| + | [[File:PD cutaway.png|300px|thumb|right|Section showing water and vapour paths]] | ||

| + | |||

| + | |||

| + | <gallery caption="Although easily made with hand tools, the photos below show a bench press modified to crimp 15mm pipe for a PD condenser." widths="300px" heights="300px" perrow="2" align="left"> | ||

| + | File:PDmachine1.JPG|General view. The device was all made from scrap, which explains the extraneous holes! | ||

| + | File:PDmachine2.JPG|Crimping in progress. The vertical plate on the left acts as a register to ensure the pitch and angle of the crimps are constant. | ||

| + | File:PDmachine3.JPG|Close up view. The vertical plate on the right is used to position the un-crimped section, ensuring that each crimp is square to the tube. | ||

| + | File:PDmachine4.JPG|Crimp in progress. | ||

| + | File:PDmachine5.JPG|The register is adjustable to allow the pitch of the crimps to be varied. | ||

| + | File:PDsection.JPG|Finished section of crimped tube. | ||

| + | </gallery> | ||

| + | |||

| + | |||

| + | |||

| + | |||

| + | [[Category:Biodiesel]] | ||

| + | [[Category:Processors and equipment]] | ||

Latest revision as of 00:42, 4 March 2013

The 'Plumber's delight' or PD condenser uses commonly available plumbing pipe and fittings, typically a one metre length of 22mm copper pipe with a 15mm copper pipe inside it.

Construction

22 to 15 unequal tees are used at each end to seal the inner 15mm to the outer 22mm and allow water to be passed in the gap between the two pipes, forming a water jacket around the 15mm pipe.

Before fitting the tees the stops need to be removed to allow the 15mm pipe to pass through the fittings, and then the fittings soldered to the two pipes.

Before assembly, the 15mm pipe is partially crimped at every inch or so. Each crimp should be at right-angles to the crimp before it, so as to create a turbulent vapour flow down the length of pipe and increase condensing efficiency.

Sizing and coolant

A PD condenser that is one metre long will just about keep up with a 3kW heat source when used for methanol recovery, providing the coolant water flow is adequate and is kept below 20°C.

Water should be pumped into the bottom of the condenser and returned from the top - the opposite way to the top-to-bottom flow of the hot vapour.

As a rough guide, there needs to be at least as much condenser water as there is oil in the batch.

Vegetable oil as coolant

You might be thinking, "can I use the heat from the condenser to warm the oil for the next batch?".

Yes and no. Vegetable oil is not a good medium for heat transfer, as (due to it's specific heat capacity and density) it is 2.4 times less able to absorb heat vs. the same volume of water.

However, this useful heat may be recovered using another heat exchanger, using the warm water to heat your settling oil.

- Although easily made with hand tools, the photos below show a bench press modified to crimp 15mm pipe for a PD condenser.