Difference between revisions of "Processor / tank float switch"

(Created page with "<metadesc>How to fit a float switch.</metadesc> A float switch is a device used to detect the level of liquid within a tank. The switch may be used in a pump, an indicator, an a...") |

|||

| (4 intermediate revisions by 2 users not shown) | |||

| Line 23: | Line 23: | ||

*Connectors | *Connectors | ||

| − | <gallery caption="Click pictures to enlarge" widths="300px" heights="300px" perrow="2" align=" | + | <gallery caption="Click pictures to enlarge" widths="300px" heights="300px" perrow="2" align="center"> |

File:Angled_switch.jpg|Stainless steel angled switch | File:Angled_switch.jpg|Stainless steel angled switch | ||

File:Straight_switch.jpg|Stainless steel Straight switch | File:Straight_switch.jpg|Stainless steel Straight switch | ||

</gallery> | </gallery> | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

==Fitting instructions== | ==Fitting instructions== | ||

| − | First decide on the desired position of your float switch,it needs to be off in a position that leaves a few inches of oil above the heating element,then drill a suitable hole in the tank. | + | First decide on the desired position of your float switch, it needs to be off in a position that leaves a few inches of oil above the heating element, then drill a suitable hole in the tank. |

| − | Replace any supplied rubber washers with nylon or fibre and attatch the switch | + | Replace any supplied rubber washers with nylon or fibre and attatch the switch. |

| − | Find a suitable place to site the box | + | Find a suitable place to site the box. |

| − | There will be 2 cables going in (mains power and low voltage) and 2 going out (mains and float) | + | There will be 2 cables going in (mains power and low voltage) and 2 going out (mains and float). |

| − | Drill suitable holes and insert grommets (pref atex rated) | + | Drill suitable holes and insert grommets (pref atex rated). |

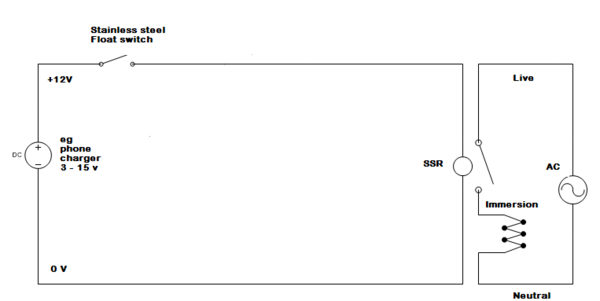

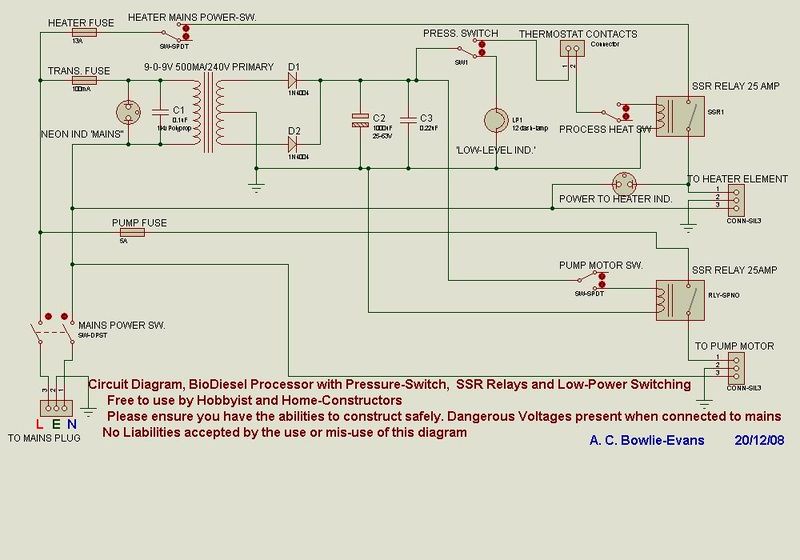

Mount the heatsink and SSR inside the box and then follow the wiring diagram. | Mount the heatsink and SSR inside the box and then follow the wiring diagram. | ||

Immersion heaters create a lot of heat through the SSR and require a heatsink to be fitted although a metal box attatched to the metal frame can also disipate the heat, as in the one shown here. | Immersion heaters create a lot of heat through the SSR and require a heatsink to be fitted although a metal box attatched to the metal frame can also disipate the heat, as in the one shown here. | ||

| Line 81: | Line 45: | ||

| − | ==SSR, Solid state relay & | + | ==SSR, Solid state relay & heat sink== |

A solid state relay (SSR) is an electronic switching device in which a small control signal controls a larger load current or voltage. It comprises a voltage or current sensor which responds to an appropriate input (control signal), a solid-state electronic switching device of some kind which switches power to the load circuitry either on or off, and some coupling mechanism to enable the control signal to activate this switch without mechanical parts. The relay may be designed to switch either AC or DC to the load. It serves the same function as an electromechanical relay, but has no moving parts. | A solid state relay (SSR) is an electronic switching device in which a small control signal controls a larger load current or voltage. It comprises a voltage or current sensor which responds to an appropriate input (control signal), a solid-state electronic switching device of some kind which switches power to the load circuitry either on or off, and some coupling mechanism to enable the control signal to activate this switch without mechanical parts. The relay may be designed to switch either AC or DC to the load. It serves the same function as an electromechanical relay, but has no moving parts. | ||

Make sure you buy from a reputable source as some imported ones can have quality issues | Make sure you buy from a reputable source as some imported ones can have quality issues | ||

| − | '''Heat sink | + | '''Heat sink''' |

Term for a component or assembly that transfers heat generated within a solid material to air or liquid for cooling. | Term for a component or assembly that transfers heat generated within a solid material to air or liquid for cooling. | ||

| Line 98: | Line 62: | ||

== Quality control == | == Quality control == | ||

| − | <gallery caption="Click pictures to enlarge" widths="300px" heights="300px" perrow=" | + | <gallery caption="Click pictures to enlarge" widths="300px" heights="300px" perrow="1" align="center"> |

| − | File:IMGP0003.jpg|Result of using sub standard components,courtesy of Mark </gallery> | + | File:IMGP0003.jpg|Result of using sub standard components, courtesy of Mark </gallery> |

== Wiring Diagram == | == Wiring Diagram == | ||

| Line 109: | Line 73: | ||

[[User:KH|KH]] 21:06, 14 July 2011 (BST) | [[User:KH|KH]] 21:06, 14 July 2011 (BST) | ||

| + | |||

| + | |||

| + | [[Category:Biodiesel]] | ||

| + | [[Category:Processor controls and instrumentation]] | ||

| + | [[Category:Vegetable oil]] | ||

| + | [[Category:Filtration & drying equipment]] | ||

Latest revision as of 23:42, 3 March 2013

A float switch is a device used to detect the level of liquid within a tank. The switch may be used in a pump, an indicator, an alarm, or other device. With any set up that contains a heating element in the liquid, it is sensible to fit a protective switch esp if methanol is present. To reduce the risk it is sensible to fit a deadlock on the heater element to ensure that it cannot be switched on unless the element is completely submerged.

Risk of methanol vapour explosion in the following circumstances:

- liquid level drops because of a leak while the processor is unattended

- leaving the element on when the processor is being drained

- turning on the element when the processor is empty

Contents

Parts list

- Solid state relay (SSR)

- Stainless steel float switch

- Heatsink

- Suitable Box

- 2.5 mm cable

- 3 - 15 V power supply

- Grommets

- Connectors

- Click pictures to enlarge

Fitting instructions

First decide on the desired position of your float switch, it needs to be off in a position that leaves a few inches of oil above the heating element, then drill a suitable hole in the tank. Replace any supplied rubber washers with nylon or fibre and attatch the switch. Find a suitable place to site the box. There will be 2 cables going in (mains power and low voltage) and 2 going out (mains and float). Drill suitable holes and insert grommets (pref atex rated). Mount the heatsink and SSR inside the box and then follow the wiring diagram. Immersion heaters create a lot of heat through the SSR and require a heatsink to be fitted although a metal box attatched to the metal frame can also disipate the heat, as in the one shown here.

- Click pictures to enlarge

SSR, Solid state relay & heat sink

A solid state relay (SSR) is an electronic switching device in which a small control signal controls a larger load current or voltage. It comprises a voltage or current sensor which responds to an appropriate input (control signal), a solid-state electronic switching device of some kind which switches power to the load circuitry either on or off, and some coupling mechanism to enable the control signal to activate this switch without mechanical parts. The relay may be designed to switch either AC or DC to the load. It serves the same function as an electromechanical relay, but has no moving parts.

Make sure you buy from a reputable source as some imported ones can have quality issues

Heat sink

Term for a component or assembly that transfers heat generated within a solid material to air or liquid for cooling.

- Click pictures to enlarge

Quality control

- Click pictures to enlarge

Wiring Diagram

KH 21:06, 14 July 2011 (BST)