Difference between revisions of "Cone bottoms for tanks"

| Line 4: | Line 4: | ||

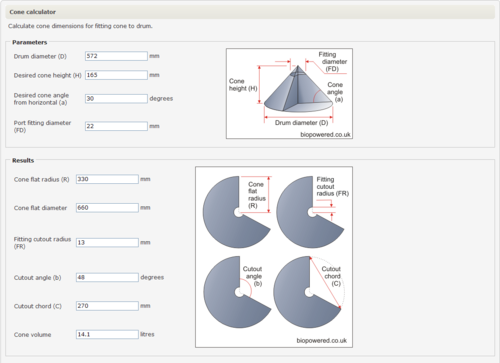

[[File:Cone_Calculator_grab.png|500px|thumb|right|Cone calculator: source Tony.]] | [[File:Cone_Calculator_grab.png|500px|thumb|right|Cone calculator: source Tony.]] | ||

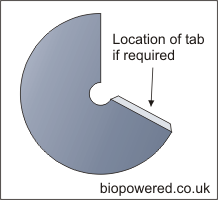

| − | + | [[File:Cone_bottom_tab.png]] | |

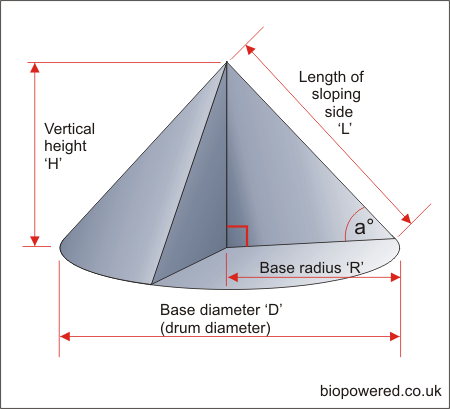

[[File:Conebottom1.png]] | [[File:Conebottom1.png]] | ||

Revision as of 22:29, 12 September 2012

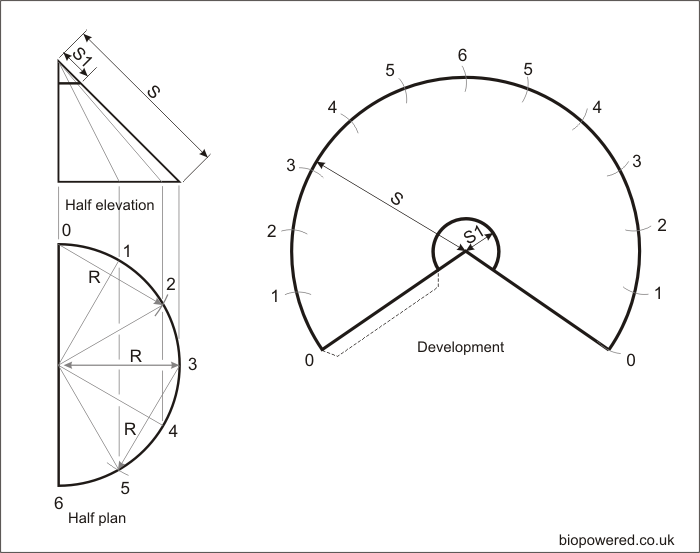

Forget the hole in the top for the time being so, to find length of sloping side ‘L’

Base dia ‘D’ = 570mm (typical for a 205 litre steel drum, but check before proceeding) hence base radius ‘R’ is half this = 285 Desired angle ‘a’, say = 45°

For any size cone where angla a is 45° L = Square root of 2 (1.414) x R

To address the hole in the top, use the same formula but substitute the diameter of the fitting you want to use for the base diameter, say 30mm

Hence if D = 30, R will = 15

l = Square root 2 (1.414) x 15 = 21.21

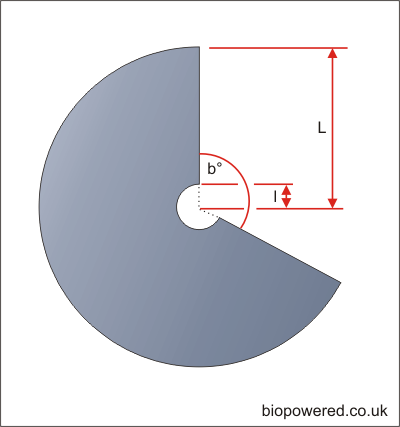

We are aiming for this shape to roll into the cone,

so we need to know the angle between the two edges (b°).

We’ve already calculated L, 403mm.

The Included angle is simple to work out it's 180 x D / L

Giving us 180 x 570 / 403 = 254.59°

To fabricate a 60° cone draw a semi-circle with a radius equal to the finish diameter, for a steel drum that's 570mm. The hole at the apex is the same, use a radius the same as the finished diameter.

- Steps in producing a cone bottom