Difference between revisions of "Cone bottoms for tanks"

| Line 32: | Line 32: | ||

We know the outer arc length (x) is the same length as the circumference as the drum so we can calculate this using the formula C = π x d, where C is the circumference of the circle | We know the outer arc length (x) is the same length as the circumference as the drum so we can calculate this using the formula C = π x d, where C is the circumference of the circle | ||

| − | + | ||

| + | <gallery caption="Steps in producing a cone bottom" widths="400px" heights="500px" perrow="2" align="left"> | ||

| + | File:Conebottomphoto1 source rob-b.jpg|Blank for cone. Source: Rob-b | ||

| + | File:Conebottomphoto2 source rob-b.jpg|Arc for cone cut from blank. Source: Rob-b | ||

| + | File:Conebottomphoto3 source rob-b.jpg|Arc formed to cone and tack welded Source: Rob-b | ||

| + | File:Conebottomphoto4 source rob-b.jpg|Finished cone with fitting welded to tank. Source: Rob-b | ||

| + | </gallery> | ||

Revision as of 23:18, 21 January 2012

This is currently a draft page for JamsRL's scrutiny.

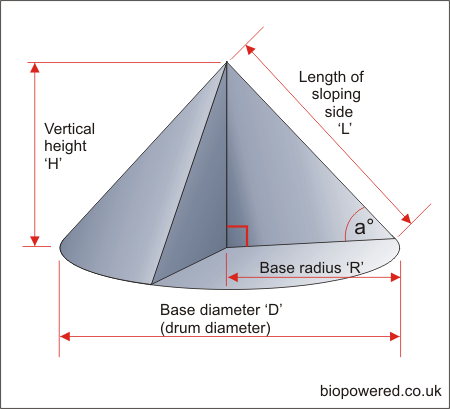

Forget the hole in the top for the time being so, to find length of sloping side ‘L’

Base dia ‘D’ = 570mm (typical for a 205 litre steel drum, but check before proceeding) hence base radius ‘R’ is half this = 285 Desired angle ‘a’, say = 45°

L= R/Cos a L= 285/Cos 45 (Cos being Cosine, available on many calculators or the internet) L = 403mm

To address the hole in the top, use the same formula but substitute the diameter of the fitting you want to use for the base diameter, say 30mm Hence if D = 30, R will = 15

l = 15/Cos 45 l = 21.2mm

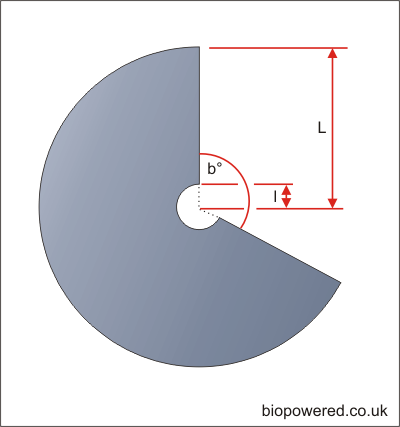

We are aiming for this shape to roll into the cone,

so we need to know the angle between the two edges (b°).

We’ve already calculated L, 403mm.

We know the outer arc length (x) is the same length as the circumference as the drum so we can calculate this using the formula C = π x d, where C is the circumference of the circle

- Steps in producing a cone bottom