After having a few problems with waxing as explained here

http://www.biopowered.co.uk/forum/index.php/topic,1585.0/topicseen.htmlI have been looking into what maybe causing it and how to prevent it.

I had thought that putting Coldflow into my finished Bio would keep it usable down below 0 °C but was shocked when I had wax forming in the bio that blocked a J cloth within a litre or so being filtered when the temp dropped to 8 °C overnight and about 10 °C during the day, towards the end of September.

Since my wife and kids use the car without me, including trips down country lanes in the evenings I really had to get it sorted so it wouldn't break down on her. So it was off to the tax station again temporarily, focuses the solution finding mind

My Process:

My Process:Liquid oil, rapeseed/soya mix, usually no more than 5% solids, glyc washed, well dried 2 stage ASM non tit, after 2nd stage clear pass on the 10/90 drain 2nd stage glyc and demeth, acid wash with vinegar and 10L of water. Further washes till clear, final filter through a j cloth before a 1micron sock.

So information I had and clues I gathered:Wax seemed to form when temp drops below 11 °C

Apparently according to Uncleh on VOD who gets the same wax build up, if he does not demeth but just washes he doesnt get it.

I believe Nigelb has stated he doesn't get this wax and he does a water prewash and doesn't recover methanol so methanol is still present.

My first batch that I made some mistakes with had a lot of methanol still in it when I washed it, I still had a jar sample of this and when I stuck it in the fridge at 5 °C there was no wax build up.

It has been mentioned that there are maybe 2 different types of wax/HMPEs that form, one at low temps (0 °C to minuses) and one at higher temps (the wax I had)

So I did some research to try to find something that could be:

Present in bio at below 11C but not when warmer.

Not washed out by just water washing.

Reduced by water washing with methanol present by not demething or by doing a water prewash.

I thought maybe the 'wax' must already be in there and was not being converted to Bio during the process so I looked at what was in the feedstock. Free Fatty acids are present depending on the source of the oil, amounts vary due to the source. These are not really converted very well with alkaline catalyst and what isn't converted usually combines with any water to form soap, hence the need for dry oil, a titration is used to measure the level of ffa's in your feedstock thus allowing you to add the correct weight of catalyst above the chosen base figure. FFA's are then turned into soap when the methoxide is introduced into the reactor.

Obviously soap is formed in the reaction and this is what is washed out once it is completed.

BUT...When I looked at the types of FFAs typically found in the feedstock there was one that stood out,

Oleic AcidFrom Wikipedia

http://en.wikipedia.org/wiki/Oleic_acidAppearance - Pale yellow or brownish yellow oily liquid with lard-like odor

Melting point - 13-14 °C

Solubility in water - Insoluble

Solubility in methanol - Soluble

It appears in the following amounts:

The majority of olive oil

20-85% of sunflower oil

37-56% of chicken and turkey fat

44-47% of lard

So in conclusion could some Oleic Acid pass through the bio processing as it:

Doesn't convert well using base catalyst just like all FFAs.

It doesn't turn to soap as it is not soluble in water.

It doesn't show up in the 10/90 test as it is soluble in methanol.

It turns to a yellowish lard/wax below 13 °C and this appears to be what I have?

This may explain why some get this and some don't, it depends on feedstock, amount of olive oil/sunflower oil present, what's cooked in it, etc, etc. My thinking is that when methanol is present in the bio the Oleic acid is dissolved by it and it is then washed out in the water washes with the methanol. If the bio is demethed the Oleic acid is still contained within the bio as bigger molecules that are not soluble so are not washed out.

Non water washers probably see this at the bottom of their settling drums and it is generically called 'soap'.

I was told to filter oil as I needed it and keep a sample outside so I would know when the wax/HMPEs had formed, trouble with that is if there is a cold spell and the bio is in the car for a few days I'm screwed.

So to solve this I have got a cheap chest freezer for £25 and wired a PID and SSR on it. I've cooled 20 litres of bio down to 0 °C so the wax forms, filtered it through a pillow case to take out the worst of it then through my final filter of J cloth and 1 micron sock.

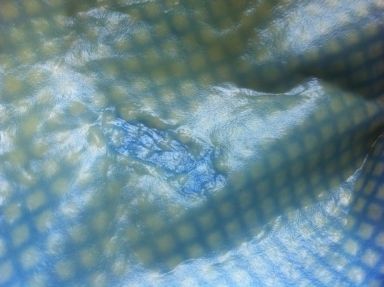

This is it at 0 °C. That is condensation on the jar the bio is clear.

I let it warm to ambient then cooled it again to 0 °C nothing in it still clear.

Even at -4 °C its getting cloudy but still liquid, I suppose this is the coldflow doing its job.

My finishing process from autumn through to spring now will include cooling the washed bio down to at least 3 °C below the average temp for the time of year before final filtering. This will hopefully mean I will not get caught by any cold snaps or need to fix the car at the side of the road, or rescue the wife.

Many will say don't bother or what I have described is rubbish as what they do completely contradicts what I have said, but when my family is going off in the car I want them to come back safe and I'm a worrier.

This seems to be working for me but others may not agree that is their prerogative.

All I know is if the car broke down she would NEVER let me hear the end of it so I will be doing what seems to work for my bio from now on....