Now then...for the laymen among us who are not mathmatically adept could someone please explain the two venturi formulas.

I have always made venturi's to the throat size's that Jim gave me ie 40/60 =8mm, 80=9.2 mm, 120= 10.8mm

I don't pretend to understand the formula's listed in the wiki but would appreciate being shown, with examples, what everything means and how it's calculated.

Thanks

Nige

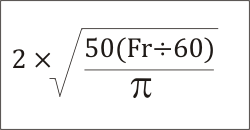

Being particularly thick myself, I'll have a go at putting it in the Noddy speak I understand, but to show worked examples involving the square root sign is a little tricky. To show the formulas I had to make a graphic in a vector program and export as a bitmap.

But here goes ...

Fr equals the pump flow rate, so with a TAM that's 40 litres/min. So stick 40 in the formula in place of Fr. Next step is to work out the sum in the brackets (sort of mathematical rule because every thing in the brackets is just one item). so the brackets become 40 divided by 60 which is 0.6666. Having done that sum and reduced the bracket to a single number, you can now ditch the brackets.

The top line now becomes 50 times 0.6666 (sort of another mathematical rule, two numbers next to each other means multiply).

So top line now becomes 33.33.

Not quite sure how deep to delve into Noddy speak, so I'll delve deep! The little symbol that looks like a truncated capital H under the line is Pi. It's a number which was worked out by someone just a bit cleverer than me and something that you will just have to take for granted 'cos I can't explain how it's worked out. It's a fraction that goes on indefinitely, but for what we want 3.142 will be fine.

So under the tick thing you now have 33.33 above the line and 3.142 below. The line means divide, so the sum is 33.33 divided by 3.142 which is 10.6078

Now you just have one number, 10.6078 under the tick thing. The tick thing is a square root symbol and applies to everything under it. Easiest way to work this out is on a calculator with a square root symbol or just bang "square root 10.6078" into Google. This gives 3.2569. having done the square root you can forget about the tick thing.

So you're left with 2 times 3.2569 which is 6.51. This is the size of the throat in mm.

For 60 litres/min it works out at 7.876

Using the other formula, it's simply the square root of the flow rate. So for 40 litres/min it's 6.324mm and for 60 litres/min it's 7.745mm, so very little difference between the two sets of answers, but the latter is much easer to use.

Hope that A) is correct, and B) made sense!