Here you go.

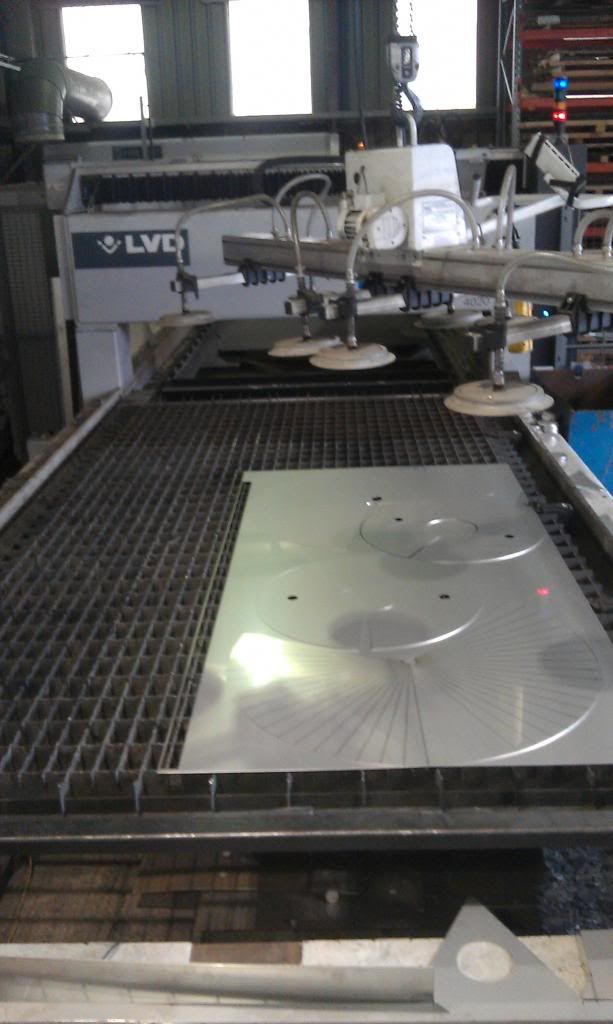

First off cutting the developed flat patterns for the cones on the laser, complete with etching the bend lines on.

[imghttp://i250.photobucket.com/albums/gg248/bertle500/IMAG0215_zps2de02a57.jpg]http://[/img]

Pressing the cones (not me, I was taking the pictures).

Rolling the main tank bodies

A spot of TIG welding

Main body, inner cone and extension to take the outer cone

And with the second cone on

And there you go pumps on, legs on and plumbed up. The venturi has now been moved up the pipe due to popular demand.