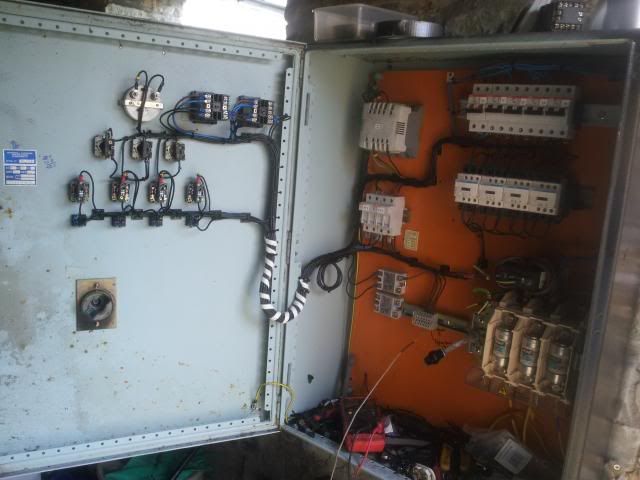

Made from scavenged bits of industrial hardware!

4 contactors driving two heaters and two pumps. Individual double pole breakers, and a BIG switch.

The control side runs at 24V bringing in the contactors on demand. On the heaters, the PID controller will inhibit the contactor if the controller is in alarm - so if the SSR fails closed circuit, the contactor will come out and stop the heater.Washing machine pressure switches will also inhbit the heater.

The VFD for the processor pump is mounted elsewhere, so there are no controls for that on the panel (yet).

I managed to keep the original ammeter on the front - it was originally 0-200A, but I wrapped the current transformer 10 times so it reads over by 10x (i.e. it reads 100A for 10A). I'm not convinced by how accurate it is, but it gives a clue as to how much power the plant is drawing.

Further plans include controls for the VFD, a flashing siren if something goes into alarm (over temperature, low level etc), and a switch/light for the condenser cooling pump. And perhaps some kind of internet integration.

a.ninja.is is something I'm using for a few other things around the home, extending it to the plant wouldn't be too hard.