Difference between revisions of "Processor - with pre-heat / drying tank"

| Line 9: | Line 9: | ||

{{#ev:youtube|s23ruU7v3mk|300|middle|TT700 video}} | {{#ev:youtube|s23ruU7v3mk|300|middle|TT700 video}} | ||

| − | [[File: | + | [[File:TT700A 01.jpg|200px|thumb|left|alt text]] In the photo above, it can be seen that an air operated main pump and mixing ram is used ,whilst smaller models can be hand operated. The left hand heating tank is open at the top and has a high quality level sensor built into it's side to ensure that the heater elements are not turned on accidentally. Most accidents in making biodiesel have been caused this way, especially if the plant design allows methanol vapour to be present at any time in the heating tank during the process. This design does not allow this to happen. |

| + | |||

[[Category:Biodiesel Processors]] | [[Category:Biodiesel Processors]] | ||

Revision as of 07:45, 3 December 2010

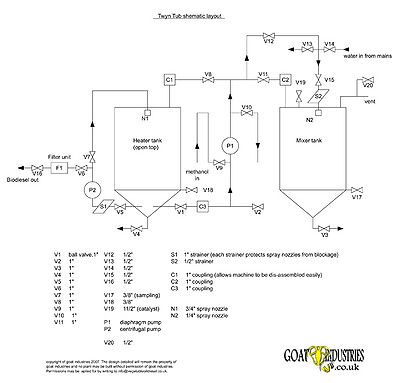

The Twyn Tub or 'TT' range of processors are an industrial type of design that produces biodiesel to the European standard, EN14214. The process starts off in the left hand tank, that has heating elements inserted and the main reaction takes place in the right hand tank, which is compltely free of any electrical items. The plant was designed to be as safe as reasonly possible without using extortionately expensive components and isolating the reaction stage of the process was found to be the most cost effective way of doing this.

- TT700A

The plant has a large number of valves, inlets and outlets to enable the pumps to work in a large number of different permutations, making the plant as a whole extremely flexible. A separate, electric pump, is used on the left hand side to avoid contamination of the final product with fluids in the main air operated pump. The process uses water to purify the biodiesel, with spray nozzles for washing and drying. No ionic exchange resins are used as these turn the soaps back to acids which are corrosive to vehicle engine parts.

In the photo above, it can be seen that an air operated main pump and mixing ram is used ,whilst smaller models can be hand operated. The left hand heating tank is open at the top and has a high quality level sensor built into it's side to ensure that the heater elements are not turned on accidentally. Most accidents in making biodiesel have been caused this way, especially if the plant design allows methanol vapour to be present at any time in the heating tank during the process. This design does not allow this to happen.