Difference between revisions of "Processor - with pre-heat / drying tank"

| Line 5: | Line 5: | ||

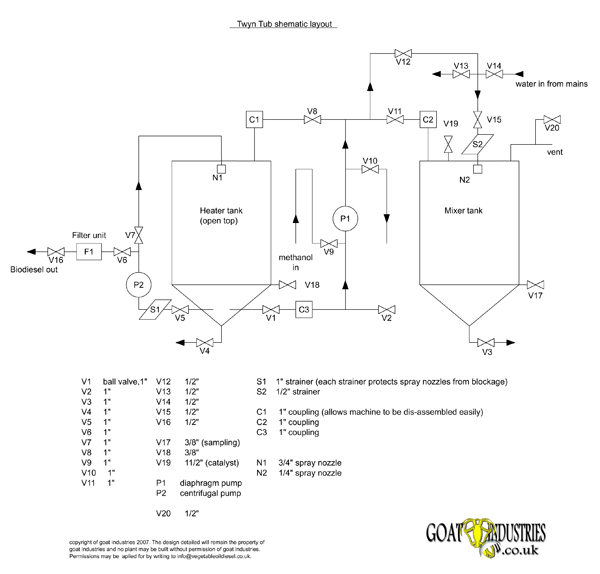

File:Schematic_diagram.jpg|The plant has a large number of valves, inlets and outlets to enable the pumps to work in a large number of different permutations, making the plant as a whole extremely flexible. A separate, electric pump, is used on the left hand side to avoid contamination of the final product with fluids in the main air operated pump.</gallery> | File:Schematic_diagram.jpg|The plant has a large number of valves, inlets and outlets to enable the pumps to work in a large number of different permutations, making the plant as a whole extremely flexible. A separate, electric pump, is used on the left hand side to avoid contamination of the final product with fluids in the main air operated pump.</gallery> | ||

| − | [http://www.youtube.com/watch?v=s23ruU7v3mk | + | [http://www.youtube.com/watch?v=s23ruU7v3mk TT700A video on Utube] |

Revision as of 19:07, 30 November 2010

The Twyn Tub or 'TT' range of processors from Goat Industriesare an industrial type of design that produces biodiesel to the European standard, EN14214. The process starts off in the left hand tank, that has heating elements inserted and the main reaction takes place in the right hand tank, which is compltely free of any electrical items. The plant was designed to be as safe as reasonly possible without using extortionately expensive components and isolating the reaction stage of the process was found to be the most cost effective way of doing this.

- TT700A

The plant has a large number of valves, inlets and outlets to enable the pumps to work in a large number of different permutations, making the plant as a whole extremely flexible. A separate, electric pump, is used on the left hand side to avoid contamination of the final product with fluids in the main air operated pump.