Difference between revisions of "Importance of venting a processor"

m (moved Importance of venting a processer to Importance of venting a processor: Speeling) |

|||

| Line 1: | Line 1: | ||

| − | + | __TOC__ | |

| − | + | ||

| + | ==Introduction== | ||

| + | |||

| + | |||

| + | It is imperative that all Biodiesel processors be vented safely to atmosphere via an un-valved pipe. All the processor designs shown on this wiki are vented. | ||

| + | |||

| + | A vent will not mitigate an explosion. The generation of gas in an explosion is far too rapid for the vent to cope. | ||

| − | + | The vent is designed to allow air to be displaced when filling with oil, adding Methoxide or to be entrained into the processor when pumping out finished Biodiesel. It will also allow the contents to safely expand and contract when heating and cooling. | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | ||

| + | ==Simple vents== | ||

| + | [[File:Appleseed_processor_schematic.png|250px|thumb|right|Vented path direct from processor tank shown in red.]] | ||

| + | On a processor without methanol recovery i.e. no vapour circuit, the vent can be a simple small bore pipe with no valves from the ullage space of the processor, leading outside and terminating safely as far away from human contact as possible. | ||

| + | |||

| + | On the Appleseed processor, right, there is an additional vent which incorporates a relief valve which would operate in the event of the main vent becoming blocked. | ||

| + | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| + | <br> | ||

| + | <br> | ||

| + | <br> | ||

| + | <br> | ||

| + | <br> | ||

| + | <br> | ||

| + | <br> | ||

| + | <br> | ||

| + | ==Vents on a GL type processor== | ||

| + | [[File:GL processor with vent path in red.png|400px|thumb|right|Vented path for processor shown in red.]] | ||

| + | Whilst it's possible to vent a GL type processor, direct from the tank, it is more ecologically beneficial to install the vent on the vapour line, after the condenser (highlighted in red in the top graphic). This way any methanol fumes that are released during the reaction, or in the de-meth stage, will get condensed off and collected instead of being released to atmosphere. | ||

| + | <br> | ||

| + | [[File:Fan and circuit dia.png|150px|thumb|left]] | ||

| − | + | Because the vent is on the vapour circuit, one of the most commonly asked questions is why doesn't the venturi blow vapour from the vent. The answer is best described by the diagram below where the fan is located in a chamber. It blows the same volume of air out of the chamber to the left, as it sucks in from the right, so it creates a circulation. There is no vacuum or pressure in the circuit, therefore no air sucks in through, or blows out of, the vent. | |

| + | The theory is exactly the same in the processor, except in place of a fan you have a venturi (far safer as there are no moving parts). The only time air will come out of the vent is when you add oil or Methoxide to the processor or when the oil and air expand whilst heated. Similarly when you drain glycerol or pump out the finished biodiesel, the vent will suck air back in. | ||

| + | <br> | ||

| + | <br> | ||

| − | |||

| + | On any vent arrangement, the safest material to use is rigid pipe, preferably metal. Soft flexible pipe work can kink or be flattened by things leaning against it and are also susceptible to the effects of heat, compounding other issues. | ||

| + | <br> | ||

| + | <br> | ||

| + | <br> | ||

| + | <br> | ||

| + | <br> | ||

| + | ==Consequences== | ||

| − | If the vent becomes blocked | + | If the vent becomes blocked a build up of positive or negative pressure can occur. This will have sever effects on the most vunerable part of the system, namely the reactor tank. |

| − | |||

| − | Negative pressure can and will cause the reactor to implode | + | ===Negative pressure=== |

| + | As seen in these pictures negative pressure can and will cause the reactor to implode . This is due to the atmospheric pressure on the out side of the tank pushing inwards. | ||

| − | <gallery caption="This is a steel, cone bottomed drum" widths=" | + | <gallery caption="This is a steel, cone bottomed drum" widths="250px" heights="200px" perrow="3"> |

File:Collapsed processor 1.jpg|Reactor still with insulation on. | File:Collapsed processor 1.jpg|Reactor still with insulation on. | ||

File:Imploded-reactor-3.jpg|With the insulation removed you can see just how damaged it is. | File:Imploded-reactor-3.jpg|With the insulation removed you can see just how damaged it is. | ||

| Line 74: | Line 77: | ||

</gallery> | </gallery> | ||

| − | These photos were supplied by | + | These photos were supplied by BassAddict. |

| − | The reason his reactor imploded was he had used flexible hose for his vent, this got a small restriction in it and the negative pressure created when the bio was pumped out collapsed the | + | The reason his reactor imploded was he had used flexible hose for his vent, this got a small restriction in it and the negative pressure |

| − | This is why we advocate using | + | |

| + | created when the bio was pumped out collapsed the pipe sealing the vent. | ||

| + | This is why we advocate using rigid pipe for the vents. | ||

| − | |||

<BR> | <BR> | ||

| Line 85: | Line 89: | ||

| − | The most likely way to produce positive pressure in a GL is by pumping oil into it with a closed vent, although in most cases it is unlikely | + | The most likely way to produce positive pressure in a GL is by pumping oil into it with a closed vent, although in most cases it is unlikely |

| − | However if a reactor full of cold oil was heated with a closed vent this could build up a surprising amount of pressure. | + | the pump will produce enough pressure to cause a problem. |

| + | |||

| + | However, if a reactor full of cold oil was heated with a closed vent this could build up a surprising amount of pressure. | ||

It is possible the the reactor or pipework could rupture, but an explosion is highly unlikely in this scenario. | It is possible the the reactor or pipework could rupture, but an explosion is highly unlikely in this scenario. | ||

| + | <br> | ||

| + | <br> | ||

| + | |||

| + | |||

| + | |||

| + | [[Category:Biodiesel]] | ||

| + | [[Category:Processors and equipment]] | ||

Revision as of 22:03, 3 February 2013

Contents

Introduction

It is imperative that all Biodiesel processors be vented safely to atmosphere via an un-valved pipe. All the processor designs shown on this wiki are vented.

A vent will not mitigate an explosion. The generation of gas in an explosion is far too rapid for the vent to cope.

The vent is designed to allow air to be displaced when filling with oil, adding Methoxide or to be entrained into the processor when pumping out finished Biodiesel. It will also allow the contents to safely expand and contract when heating and cooling.

Simple vents

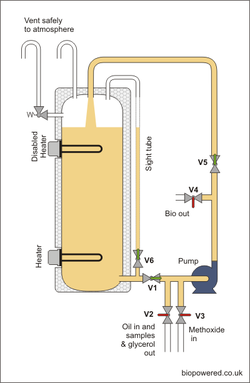

On a processor without methanol recovery i.e. no vapour circuit, the vent can be a simple small bore pipe with no valves from the ullage space of the processor, leading outside and terminating safely as far away from human contact as possible.

On the Appleseed processor, right, there is an additional vent which incorporates a relief valve which would operate in the event of the main vent becoming blocked.

Vents on a GL type processor

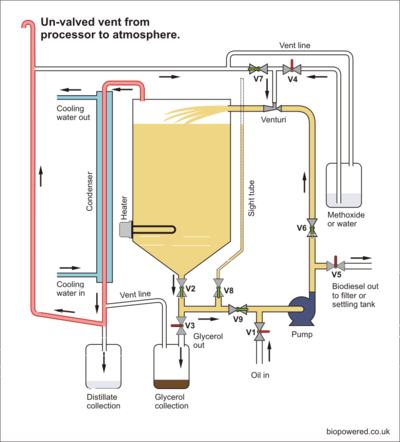

Whilst it's possible to vent a GL type processor, direct from the tank, it is more ecologically beneficial to install the vent on the vapour line, after the condenser (highlighted in red in the top graphic). This way any methanol fumes that are released during the reaction, or in the de-meth stage, will get condensed off and collected instead of being released to atmosphere.

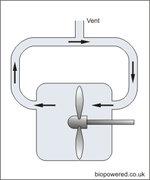

Because the vent is on the vapour circuit, one of the most commonly asked questions is why doesn't the venturi blow vapour from the vent. The answer is best described by the diagram below where the fan is located in a chamber. It blows the same volume of air out of the chamber to the left, as it sucks in from the right, so it creates a circulation. There is no vacuum or pressure in the circuit, therefore no air sucks in through, or blows out of, the vent.

The theory is exactly the same in the processor, except in place of a fan you have a venturi (far safer as there are no moving parts). The only time air will come out of the vent is when you add oil or Methoxide to the processor or when the oil and air expand whilst heated. Similarly when you drain glycerol or pump out the finished biodiesel, the vent will suck air back in.

On any vent arrangement, the safest material to use is rigid pipe, preferably metal. Soft flexible pipe work can kink or be flattened by things leaning against it and are also susceptible to the effects of heat, compounding other issues.

Consequences

If the vent becomes blocked a build up of positive or negative pressure can occur. This will have sever effects on the most vunerable part of the system, namely the reactor tank.

Negative pressure

As seen in these pictures negative pressure can and will cause the reactor to implode . This is due to the atmospheric pressure on the out side of the tank pushing inwards.

- This is a steel, cone bottomed drum

These photos were supplied by BassAddict. The reason his reactor imploded was he had used flexible hose for his vent, this got a small restriction in it and the negative pressure

created when the bio was pumped out collapsed the pipe sealing the vent. This is why we advocate using rigid pipe for the vents.

Positive pressure

The most likely way to produce positive pressure in a GL is by pumping oil into it with a closed vent, although in most cases it is unlikely

the pump will produce enough pressure to cause a problem.

However, if a reactor full of cold oil was heated with a closed vent this could build up a surprising amount of pressure.

It is possible the the reactor or pipework could rupture, but an explosion is highly unlikely in this scenario.